Sections

Materials are the most basic part of your Warehouse, and the reason you have a Warehouse in the first place - Materials are your Inventory.

Overview

Everything you store in your Warehouse, every item you Ship out or Receive, each piece of inventory is represented by a Material. Every item you work with requires a Material in the system to represent it, and all the information about those items can be managed in the Materials Hub. Each Material in the Warehouse belongs to an Owner, and is classified within one of that Owner's Projects. Materials are configured as part of a Material Group. Materials are assigned to License Plates and are stored in a Warehouse's Locations. If using the same Materials between different Owners and Projects, you may want to create a Material Catalog rather than creating the same Materials over and over again for each Project.

Materials Hub

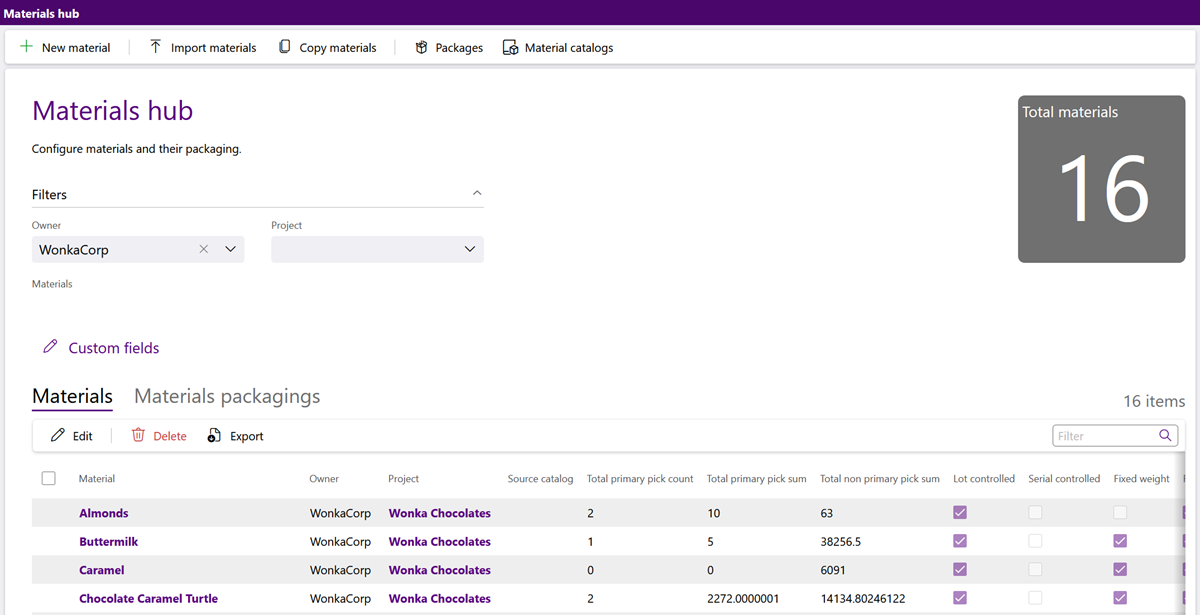

The Materials Hub allows users to create and manage all Materials, Packagings and Catalogs in Footprint. Materials and Packagings are listed in their respective tabs, in ascending alpha-numeric order. In the top, right corner is a grey square tile displaying the Total Materials.

Icons along the top of the Materials Hub allows users to Create a New Material, Manage Packagings, Copy Materials, Import Materials, and Create Material Catalogs. For the complete set of options available for Material setup, please visit our Setup a Material article.

Filters allow users to refine the listed Materials by an Owner or a Project. Users can filter further using the Material field. Users can also search by entering a Material's Code, UPC, or Description in the Search field in the top right corner of the Materials List toolbar. Any Custom Fields for Materials can be reviewed by clicking the Custom Fields option below the Filters.

The Materials and Material Packagings tabs each display their own set of information and options for managing that information. Expand the sections below for more details about each tab.

The Materials tab lists all Materials matching the filter and search criteria, in ascending alpha-numeric order. Basic information about the Materials is displayed. Selecting a Material Record will open it so the user can review and manage its details.

| Material: | The name of the Material. |

| Owner: | The Owner associated with this Material. |

| Project: | The Project under which this Material is classified. |

| Source Catalog: | The Source Catalog from which the Material is being pulled. |

| Total Primary Pick Count: | The Total Primary Pick Count for the Material. |

| Total Primary Pick Sum: | The Total Primary Pick Sum for the Material. |

| Total Non-Primary Pick Sum: | The Total Non-Primary Pick Sum for the Material. |

| Lot Controlled: |

Indicates whether or not the Material is Lot Tracked, or Controlled. |

| Serial Controlled: |

Indicates whether or not the Material is Serial Tracked, or Controlled. |

| Fixed Weight: | Indicates whether or not the Material Weight is always fixed. |

| Fixed Volume: | Indicates whether or not the Material Volume is always fixed. |

| Fixed Dimensions: | Indicates whether or not the Material Dimensions are always fixed. |

| Description: | A short description of what the Material is. |

| Edit: | Opens a window to change limited details for the selected Material: Material Group, Allocation Strategy, Shelf Life, and Status. |

| Delete: | Allows users to delete the selected Material(s) when they are no longer needed in the Warehouse(s). |

| Export: | Allows users to export the selected Material(s) details. |

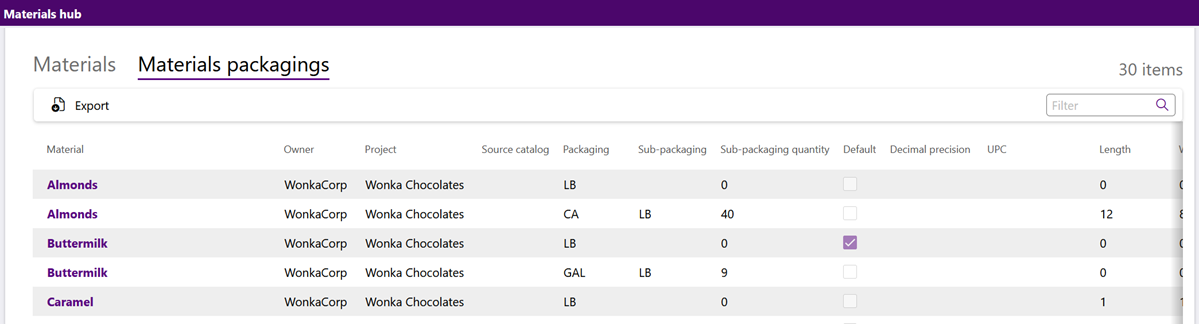

The Material Packagings tab lists all Material Packagings matching the filter and search criteria, in ascending alpha-numeric order. In the Material Packagings toolbar, there is an option to Export the selected Packagings.

| Material: | The name of the Material. |

| Owner: | The Owner associated with this Material. |

| Project: | The Project under which this Material is classified. |

| Source Catalog: | The Source Catalog from which the Material is being pulled. |

| Packaging: | The Packaging Type of the Material. |

| Sub-Packaging: | The Sub-Packaging Type of the Material. |

| Sub-Packaging Quantity: | The quantity of the Material with that Sub-Packaging. |

| Default: | When enabled, this Package level will be the default level for the Material. May be tied to Billing. |

| Decimal Precision: | Allows the Package to be split into fractions. The No Decimals setting does not allow splitting, requiring each Package to be whole; each subsequent setting (1 Decimal Place, 2 Decimal Places, etc.), allow division up to the specified decimal place. For example, the Package "Gallon" with the setting of 3 Decimal Places could have an inventory of 3.672 Gallons. |

| UPC: | Universal Product Code, unique to each level of Packaging. |

| Length: | Length of Material. Only required when the Fixed Dimensions toggle is in use. |

| Width: | Width of Material. Only required when the Fixed Dimensions toggle is in use. |

| Height: | Height of Material. Only required when the Fixed Dimensions toggle is in use. |

| L x W x H Measure: | Unit of measurement for distance. Options include meter, centimeter, foot, and inch. Only required when the Fixed Dimensions toggle is in use. |

| Weight: | Weight of the items in this Package. Only required when the Fixed Weight toggle is in use. |

| Shipping Weight: | Weight of the items in this Package, combined with the weight of the Package itself (Tare Weight). Only required when the Fixed Weight toggle is in use. |

| Weight Measure: | Unit of measurement for weight. Options include kilogram, gram, pound, ounce, ton, troy ounce, and metric ton. Only required when the Fixed Weight toggle is in use. |

| Volume: | The Volume of the Package. Footprint automatically computes a volume based on the length width and height, which is displayed underneath those measurements. Only required when the Fixed Volume toggle is in use. |

| Shipping Volume: | Volume of the Package considering any other factors that may impact the Package before Shipping. Only required when the Fixed Volume toggle is in use. |

| Volume Measure: | Unit of measurement for volume. Options include cubic meter, cubic centimeter, cubic foot, and cubic inch. Only required when the Fixed Volume toggle is in use. |

| Pallet High: | The number of this Material Packaging that can be stacked atop each other on a Pallet. |

| Pallet Tie: | The number of this Material Packaging to be placed on the first level of the Pallet before you begin stacking atop them. |

| Shippable Container: | When enabled, this Packaging can be used as an actual Shipping Container, and does not need to be packed further. |

| Autogenerate Serials: | When enabled, Serial Numbers will be automatically generated with a sequential Serial Number when prompted for this Packaging level. |

| Stack Group: | A field for entering a group name for this item when Stacked. Used for Cartonization process. |

Material Record

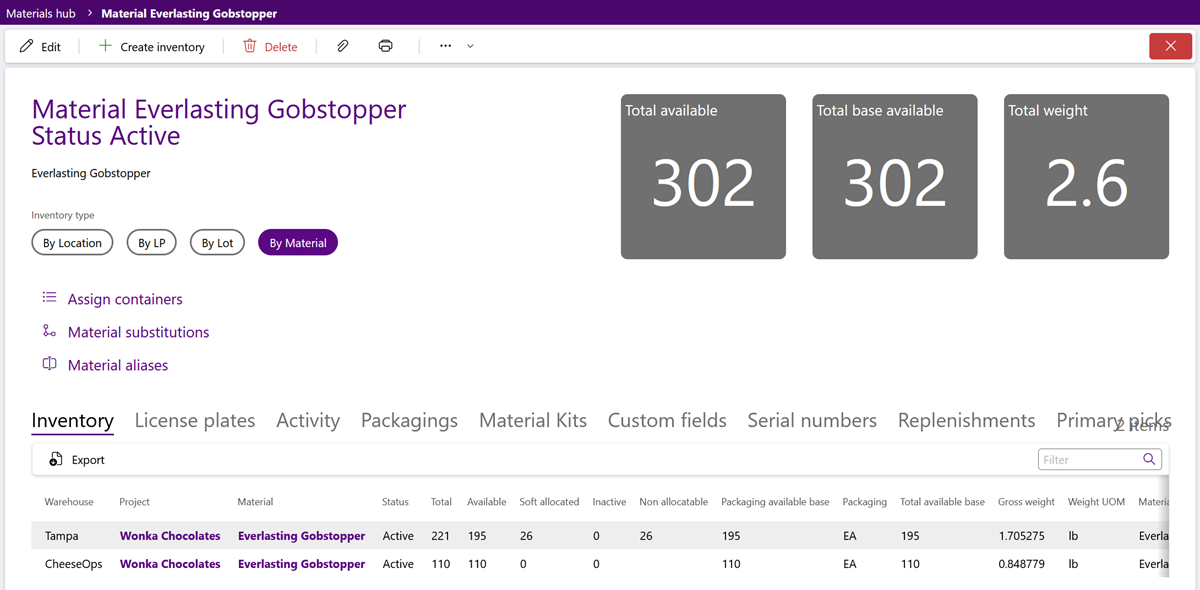

The Material record can be opened for further review and management by clicking the Material Name. The Material's basic information will be displayed, including the Name, Status, and Description. The default view is Inventory by Materials. Users can also view Material Inventory by Locations, by License Plates, or by Lots. In the top right corner are three tiles indicating the Total Available, Total Base Available, and Total Gross Weight for the Material.

Icons along the top of the Material record allows users to Edit Material Details, Create Inventory, Delete the Material, Print Material Reports or Labels, Manage Attachments, and Manage Comments. Assigned Containers, Material Substitutions, and Material Aliases can be opened for review and management. For more details on all setup options, please visit our comprehensive Setup a Material tutorial.

In addition to the Material's Name, Status, and Description displayed here, there is more information entered when creating a new Material.

Details that can be entered when creating a new Material are described in the table below. There are additional details that can only be managed when viewing a Material's Edit window.

| Code: | A short code to identify the Material by, unique to the Project. If using Barcodes, the Material's Barcode would go here. |

| Name: | The name of the Material. |

| Description: | A short description of what the Material is. |

| Owner: | The Owner associated with this Material. |

| Project: | The Project under which this Material is classified. |

| Packaging: | The Packaging for the Material being created. |

| UPC Code: | Universal Product Code, unique to each level of Packaging. Multiple UPC Codes can be entered here, each separated by a comma. |

| Group: | The Material Group associated with the Material. This will bring in Temperature Category Rules and User Defined Fields, if available. See the Material Groups section for more information. |

*Those in red are required fields.

| Allocation Strategy: |

This controls how Footprint decides which active Allocation Strategy the Material will use. (check that link to see if there are details to be added). Out-of-the-box options include Allocation Strategies with the following configurations:

|

| Tracking: |

The Material's Tracking will depend on how you will be keeping track of the Material. When keeping track of individual lots is important, select Track Lots. For Lot Tracked Materials that require individual product Serial Numbers, or tracking of unique information through Custom Fields, select Track Lots and Track Serials. If the Material is not Lot Tracked, but tracking of Serial Numbers / Custom Field information is still needed, select only Track Serials. All Material of this type will be assigned a Generic Lot, or GLot, as will any Material not being tracked at all. |

*Those in red are required fields.

| Fixed Weight: | Indicates whether or not the Material Weight is always fixed. |

| Weight: | Weight of the items in this Package. Only required when the Fixed Weight toggle is in use. |

| Shipping Weight: | Weight of the items in this Package, combined with the weight of the Package itself (Tare Weight). Only required when the Fixed Weight toggle is in use. |

| Weight Measure: | Unit of measurement for weight. Options include kilogram, gram, pound, ounce, ton, troy ounce, and metric ton. Only required when the Fixed Weight toggle is in use. |

| Fixed Volume: | Indicates whether or not the Material Volume is always fixed. |

| Volume: | The Volume of the Package. Footprint automatically computes a volume based on the length width and height, which is displayed underneath those measurements. Only required when the Fixed Volume toggle is in use. |

| Shipping Volume: | Volume of the Package considering any other factors that may impact the Package before Shipping. Only required when the Fixed Volume toggle is in use. |

| Volume Measure: | Unit of measurement for volume. Options include cubic meter, cubic centimeter, cubic foot, and cubic inch. Only required when the Fixed Volume toggle is in use. |

| Fixed Dimensions: | Indicates whether or not the Material Dimensions are always fixed. |

| Length: | Length of Material. Only required when the Fixed Dimensions toggle is in use. |

| Width: | Width of Material. Only required when the Fixed Dimensions toggle is in use. |

| Height: | Height of Material. Only required when the Fixed Dimensions toggle is in use. |

| L x W x H Measure: | Unit of measurement for distance. Options include meter, centimeter, foot, and inch. Only required when the Fixed Dimensions toggle is in use. |

*Those in red are required fields.

| Pallet High: | The number of this Material that can be stacked atop each other on a Pallet. |

| Pallet Tie: | The number of this Material to be placed on the first level of the Pallet before you begin stacking atop them. |

| Shelf Life: | The number of days the Material should be kept in the warehouse for. For a Lot Controlled Material, the Shelf Life is added to the Manufacture Date, and an Expiration Date is automatically created. |

| Storage Category Rule: | Designed to specify which Storage Category the Material belongs. |

The Material's Inventory tab is displayed by Material by default. Users can also view the Inventory list by Locations, by License Plates, or by Lots. There are also options to Assign Containers, add Material Substitutions, and add Material Aliases.

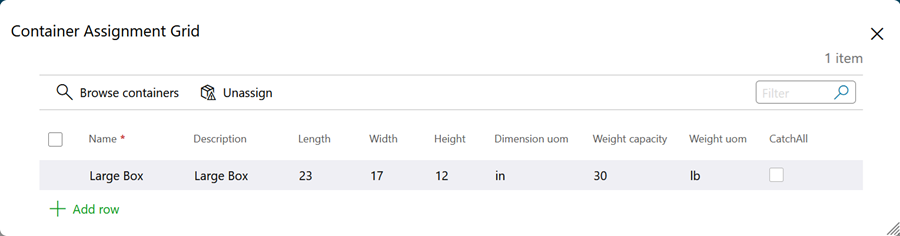

Assigned Containers for the Material can be managed here.

| Name: | The container's Name. |

| Description: | The container's Description. |

| Length: | The container's Length. |

| Width: | The container's Width. |

| Height: | The container's Height. |

| Dimension UOM: | The container's Dimension Unit of Measure. |

| Weight Capacity: | The container's Weight Capacity. |

| Weight UOM: | The container's Weight Unit of Measure. |

| Catch All: | Indicates whether or not the container can be assigned as a Catch All. |

*Those in red are required fields.

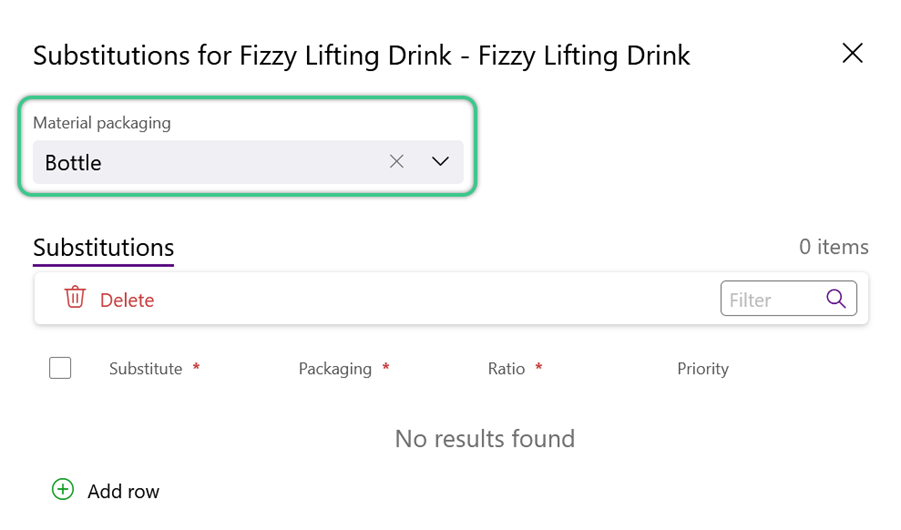

Material Substitutions allow the set up of additional Materials which could be used to replace the current Material (the Material being edited) when it is not available. These substitute Materials can be leveraged through custom Outbound Order Processing Workflows, to make decisions on Material Substitutions based on Inventory levels.

Before adding Material Substitutes, be sure to first select the Material Packaging of the current Material to be replaced by the substitute when needed.

| Substitute: | The Name of the additional Material to use in place of the current Material. This Material must be from the same Owner / Project. |

| Packaging: | The Packaging Type that should be set to Primarily Pick from this Location. |

| Ratio: | The number of Packages of the substitute Material required to replace one Package of the current Material. |

| Priority: | The Priority is used to determine which substitute Material should first be attempted as a replacement. If there is not enough inventory available, the next in line will be used. Priority starts with the lowest number and continues upwards. |

*Those in red are required fields.

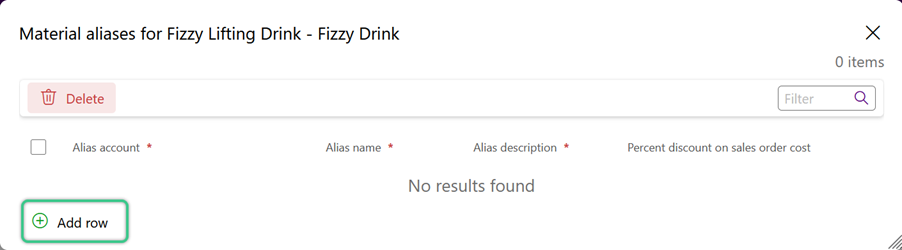

Material Aliases allows different customers to see a different Material Name when the Material is displayed in Reports and Workflows. There is also the option to reduce the sales order cost of the Material by a specified percentage for each customer account.

| Alias Account: | The Account to which this Alias can apply. |

| Alias Name: | The Name of the Material Alias. |

| Alias Description: | The description of the Material Alias. |

| Percent Discount on Sales Order Cost: | The percent discount ont he sales order cost for the Material Alias for the selected customer Account. |

*Those in red are required fields.

For more details on all setup options, please visit our comprehensive Setup a Material tutorial.

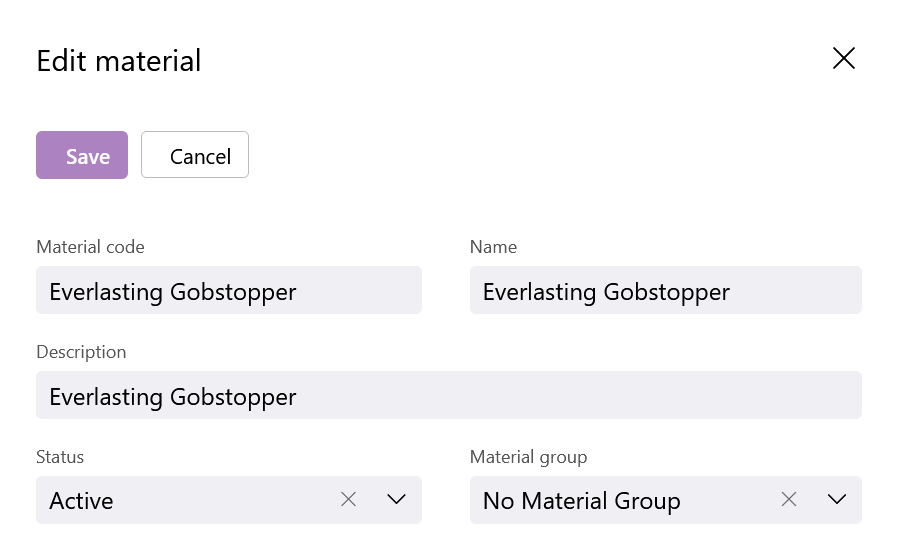

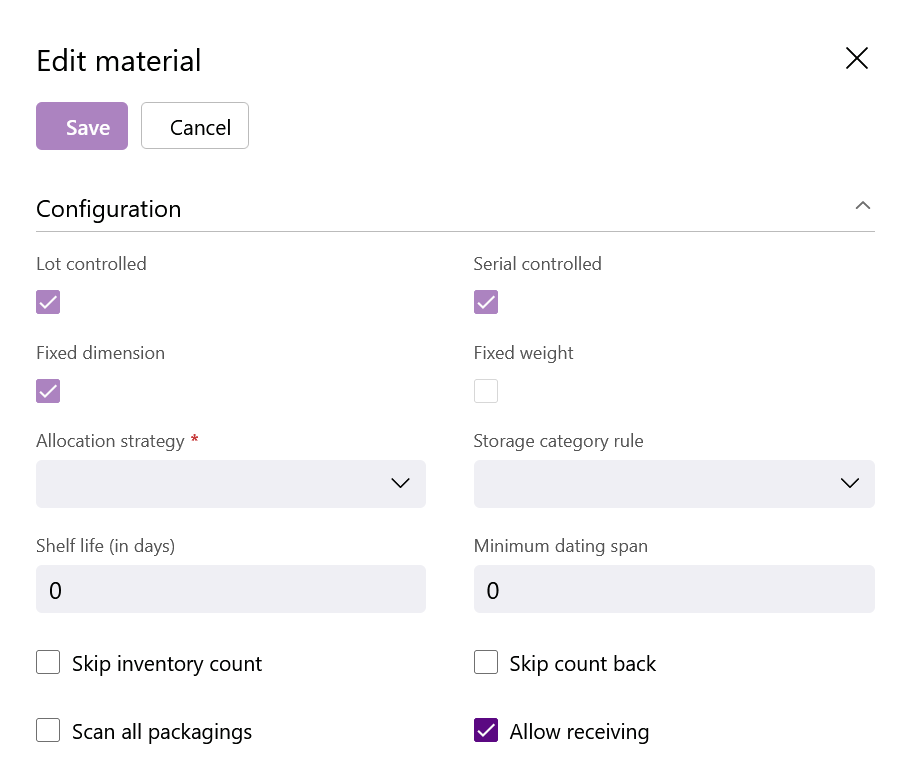

There are additional Configuration and Manufacturing setup options only available in a Material's Edit Material window. Details that can be entered during Material creation are described in the table above. The additional details that can only be entered when Editing a Material are described in the table below.

Note

Much of the information and rules set here cannot be changed while any units of this Material exist in the Warehouse. Once all of a Material's Inventory has been removed, then edits can once again be made.

| Material Code: | A short code to identify the Material by, unique to the Project. If using Barcodes, the Material's Barcode would go here. |

| Name: | The name of the Material. |

| Description: | A short description of what the Material is. |

| Status: | There are several pre-defined Statuses to choose from, as well as any custom Statuses added to your system. When a Material is created, the default Status is Active. In the future, if something has changed with the Material, you may want to change its Status. Other Status examples include Inactive, Discontinued, and Damaged. |

| Group: | The Material Group associated with the Material. This will bring in Storage Category Rules and Custom Fields, if available. |

*Those in red are required fields.

| Lot Controlled: |

Indicates whether or not the Material is Lot Tracked, or Controlled. |

| Serial Controlled: |

Indicates whether or not the Material is Serial Number Tracked, or Controlled. |

| Fixed Dimension: | Indicates whether or not the Material Dimensions are always fixed. |

| Fixed Weight: | Indicates whether or not the Material Weight is always fixed. |

| Allocation Strategy: |

This controls how Footprint decides which active Allocation Strategy the Material will use. Out-of-the-box options include Allocation Strategies with the following configurations:

|

| Storage Category Rule: | Specifies the Storage Category to which the Material belongs. |

| Shelf Life: | The number of days the Material should be kept in the warehouse for. For a Lot Tracked Material, the Shelf Life is added to the Manufacture Date, and an Expiration Date is automatically created. |

| Minimum Dating Span: | After receiving, this puts the Material on hold for the amount of days specified. |

| Skip Inventory Count: | Indicates whether or not the Material is omitted from Cycle Counts altogether. |

| Skip Count Back: | If the Owner of this material requires a Count Back after picking, this setting will override that setting and skip the Count Back for just this Material. |

| Scan All Packagings: | Indicates whether or not the Material is required to have all Packages scanned to confirm a Cycle Count. |

| Allow Receiving: | Indicates whether or not the Material is able to be received. |

*Those in red are required fields.

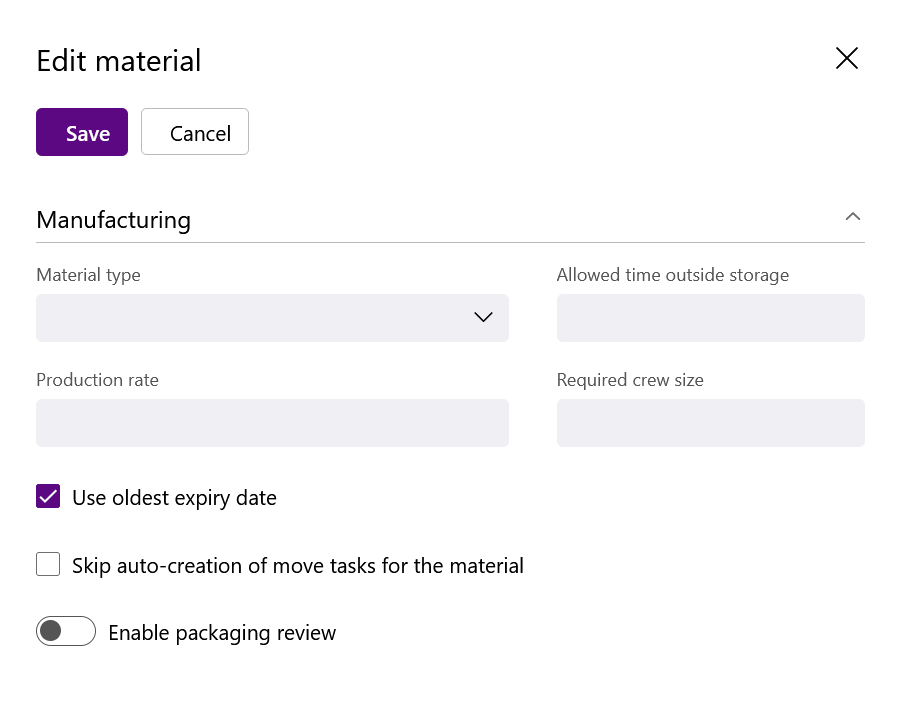

| Material Type: | Indicates if the Material used in the Manufacturing process is a Work In Progress or the Finished Product. |

| Allowed Time Outside Storage: | The amount of time (in hours) the Material can spend outside its designated Storage Category. |

| Production Rate: | The number of units of the Material that should be used per hour in Production. Setting this helps the system determine Pick Tasks. |

| Required Crew Size: | The number of people required to manufacture the Material. |

| Use Oldest Expiry Date: | Uses the oldest component's Expiration Date as the new Expiration Date in the manufactured finished product. |

| Skip Auto-Creation of Move Tasks: | Checking this box indicates the Material does not need to be relocated when being used for Manufacturing, preventing the system from automatically creating Manufacturing Move Tasks for the Material. This can be useful for liquid Materials stored in vats, for example. |

| Enable Packaging Review: | When enabled, adds the ability to Review the Material's Packaging Types. |

| Set Packaging Review Reminder: | The date the users will be prompted to perform the packaging review for the manufactured material. |

| Review New Packaging Type After (in Days): | The number of days after a new Packaging Type is created for the Material that the Packaging Type must be Reviewed. |

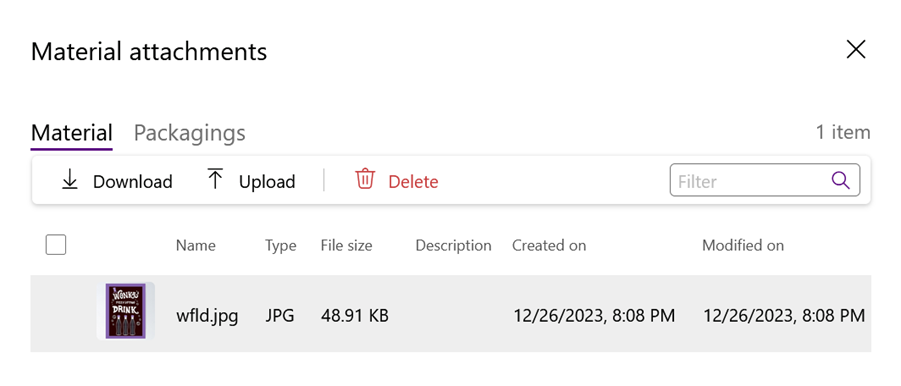

The Material Attachments window allows users to view and upload file, including images, to correspond with a Material or its Packaging. Images files added here are used throughout the rest of Footprint to assist users in visually identifying the inventory in the warehouse.

By clicking the Attachments icon in the top toolbar, users can view and manage files, including images. Basic information about the file is displayed here.

Depending on which record type the Attachments button is clicked, there may be more than one tab to which images can be added. For example, an Inbound Order record offers an Order tab and a Shipment tab, whereas a Material record offers a Material tab and a Packaging tab. Be sure to click the desired tab before clicking the Upload option.

Attachment Details

| A thumbnail image when the attachment file is an image file type. | |

| Name: | The Name of the attachment. |

| Type: | The attachment file Type. |

| File Size: | The attachment file size in pixels. |

| Description: | The Description of the attachment. |

| Created On: | The date the attachment file was uploaded. |

| Modified On: | The date the attachment file was modified. |

Clicking the Upload option opens a window to locate and select a file to be added. For step-by-step instructions, please visit our Add Attachments tutorial.

Selecting an existing file and clicking the Download option will open a confirmation window and then if confirmed, the file will be downloaded. Selecting an existing file and clicking Delete will open a confirmation window and if confirmed, the file will be deleted.

Before uploading a file to the Packaging tab, first select the Packaging Type of the Material to which the new file will be added.

While each package level can have its own image, the use of this feature is left open to your particular operation. Some warehouses prefer to put an image of the product itself (commonly referred to as an "each"). Other warehouses, particularly those with a robust hierarchy of package levels, will take pictures of each actual packaged unit and match it to the package level in Footprint. This assists in picking and packing when it may be confusing to a user whether an item is an each, case, pack, bundle, etc.

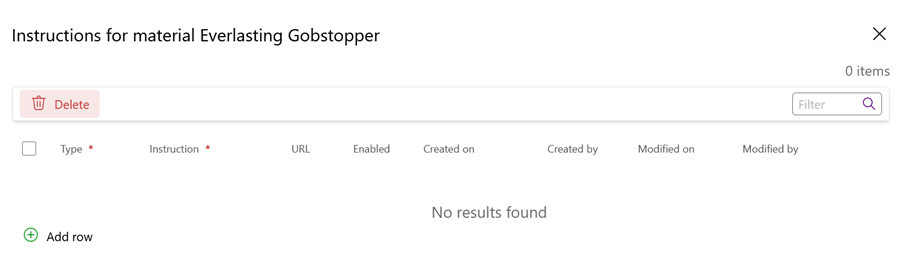

Material Instructions can be added so users know more about how to handle the Material. Material Instructions can be deleted using the Delete button in the Instructions window.

Material Instruction Details

| Type: | The Type of Instruction for the Material. Examples include: Pick, Pack, Receive, Manufacturing, Inspection, Return, Load, and more. |

| Instruction: | The specific Instruction for the Material. |

| URL: | The URL in Footprint where the Material Instruction should appear. |

| Enabled: | Indicates whether or not the Instruction is enabled onthe specified URL for all users. |

| Created On: | The date the Instruction was created. |

| Created By: | The User that created the Instruction. |

| Modified On: | The date the Instruction was modified. |

| Modified By: | The User that modified the Instruction. |

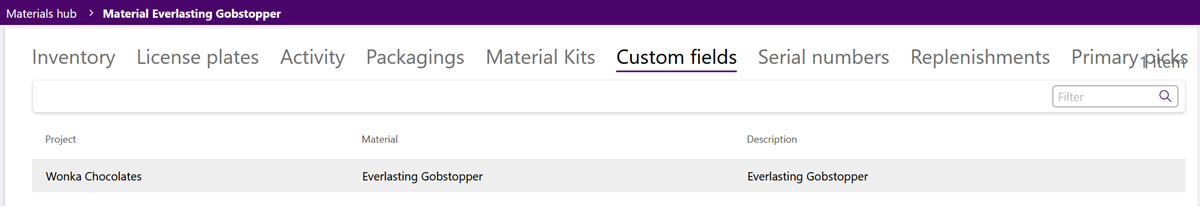

Each Material record allows the user to review the Material's Inventory, License Plates, Activity, Packagings, Kits, Custom Fields, Serial Numbers (when applicable), Replenishments, Instructions, and more. Expand the sections below for more details about each tab.

For more details on all setup options, please visit our comprehensive Setup a Material tutorial.

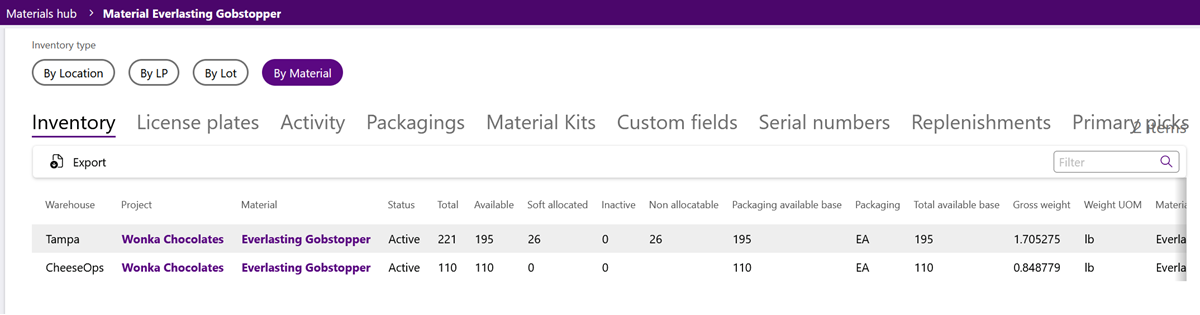

The Material Inventory tab lists all available instances of the selected Material. As users filter Materials, the tile counts in the top right corner will update to match.

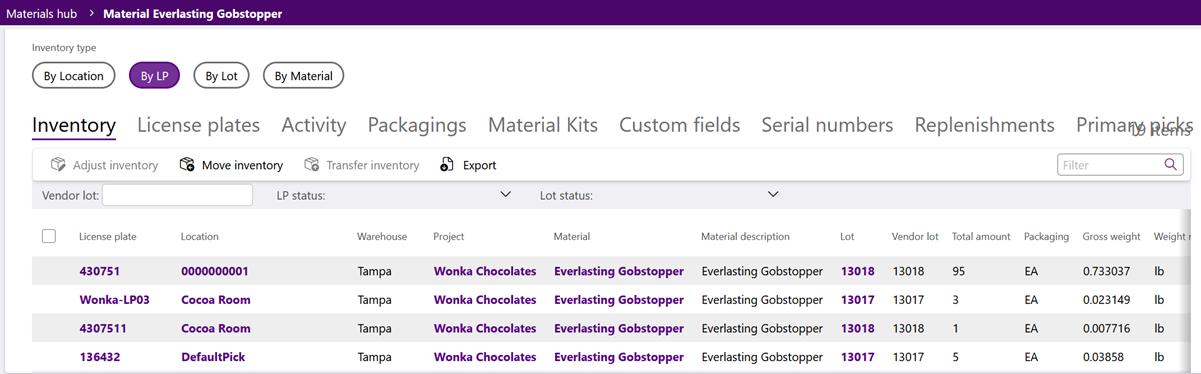

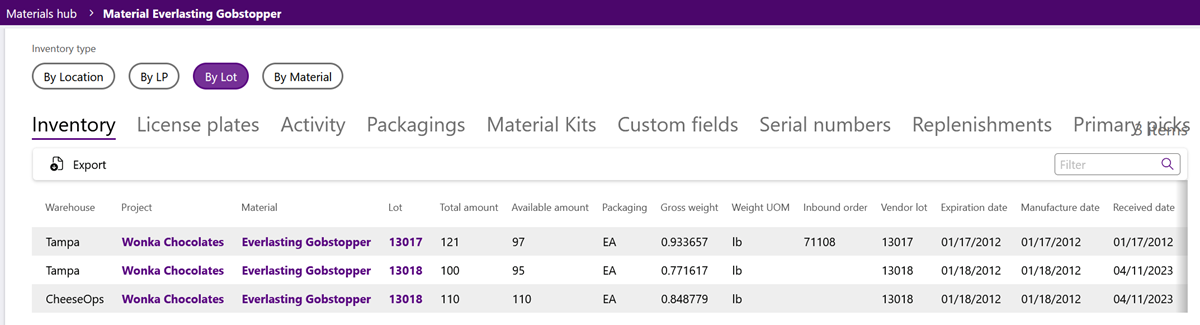

The Inventory tab is grouped by Materials by default. Material Inventory can also be grouped by Location, License Plate, and Lot. The information displayed in the Inventory tab will change depending upon the selected grouping.

Material Inventory Tab Details

Selecting a row or multiple rows allows users to Export the selected details to an Excel spreadsheet.

| Warehouse: | The Warehouse in which the Material is located. |

| Project: | The Project the Material is part of. |

| Material: | The name of the Material. |

| Status: | The status of the Material. |

| Total: | The total amount of the Material in each Warehouse listed. |

| Available: | The amount of the Material available for use in Orders. |

| Soft Allocated: | The amount of the Material which is reserved for Order(s) in the system, but not yet set aside physically. |

| Inactive: | Amount of Material stored, but not in the Active Status. |

| Non Allocatable: | The amount of the Material that is not available for Allocation. |

| Packaging Available Base: | The quantity of the Material available in its base level Packaging. |

| Packaging: | The Packaging level of the Material. |

| Total Available Base: | The total quantity of the Material available for its base level Packaging. |

| Gross Weight: | The total weight of the Material, including the Packaging. |

| Weight UOM: | The Unit of Measurement being used for the weight of the Material. |

| Material Description: | A description of the Material. |

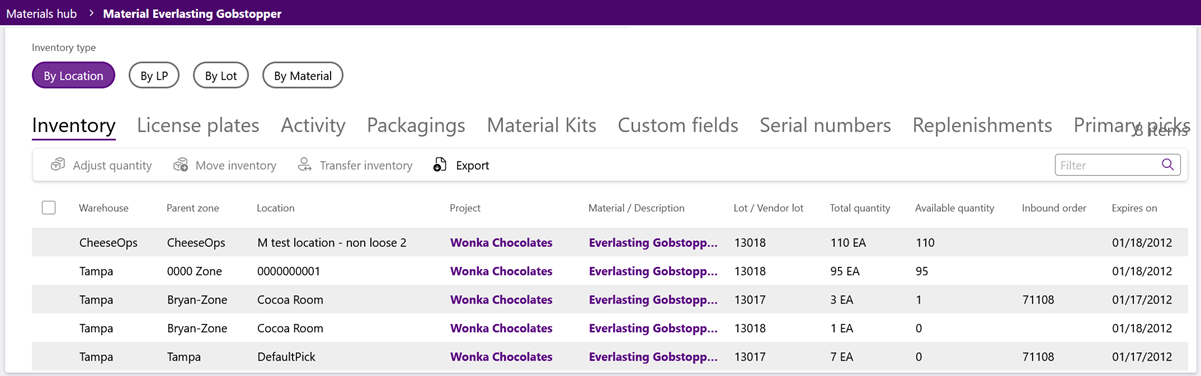

When viewing Material Inventory by Location, users have the options to Adjust Quantity, Move Inventory, Transfer Inventory, and Export details for the selected rows.

| Warehouse: | The Warehouse in which the Material is located. |

| Parent Zone: | The Parent Zone of the Warehouse in which the Material is located. |

| Location: | The physical Location of the Material in the Warehouse. |

| Project: | The Project the Material is part of. |

| Material / Description: | The name and description of the Material. |

| Lot / Vendor Lot: | The Lot and Vendor Lot the Material is part of. |

| Total Quantity: | The total amount of the Material in the Location. |

| Available Quantity: | The total amount of the Material in the Location available for use in Orders. |

| Inbound Order: | The Inbound Order that brought the Inventory into the Location. |

| Expires On: | The date the Material in the Location expires. |

When viewing Material Inventory by License Plate (LP), users can search for a specific Vendor Lot, as well as filter by LP Status and Lot Status. Clicking a License Plate from this tab will open the License Plate for review and management.

| License Plate: | The License Plate number the Material is assigned to. |

| Location: | The physical Location of the Material in the Warehouse. |

| Warehouse: | The Warehouse in which the Material is located. |

| Project: | The Project the Material is part of. |

| Material: | The name of the Material. |

| Material Description: | A description of the Material. |

| Lot: | The Lot the Material is part of. |

| Vendor Lot: | The Vendor Lot the Material belongs to. |

| Total Amount: | The total amount of the Material in the License Plate. |

| Packaging: | The Packaging level of this Material. |

| Gross Weight: | The total weight of the Material, including the Packaging. |

| Weight Measure: | The Unit of Measure being used for the weight of the Material. |

| Manufactured On: | The date the Material in the License Plate was manufactured. |

| Expires On: | The date the Material in the License Plate expires. |

| Received On: | The date the Material in the License Plate was received. |

Selecting a row or multiple rows allows users to Export the selected details to an Excel spreadsheet.

| Warehouse: | The Warehouse in which the Material is located. |

| Project: | The Project the Material is part of. |

| Material: | The name of the Material. |

| Lot: | The Lot the Material is part of. |

| Total Amount: | The total amount of the Material in the Lot. |

| Available Amount: | The amount of the Material in the Lot available for use in Orders. |

| Packaging: | The Packaging level of this Material. |

| Gross Weight: | The total weight of the Material, including the Packaging. |

| Weight UOM: | The Unit of Measurement being used for the weight of the Material. |

| Inbound Order: | The Inbound Order that brought in the Lot Inventory. |

| Vendor Lot: | The Vendor Lot the Material belongs to. |

| Expiration Date: | The date the Material in the Lot expires. |

| Manufacture Date: | The date the Material in the Lo was manufactured. |

| Received Date: | The date the Material in the Lot was received. |

| Material Description: | A description of the Material. |

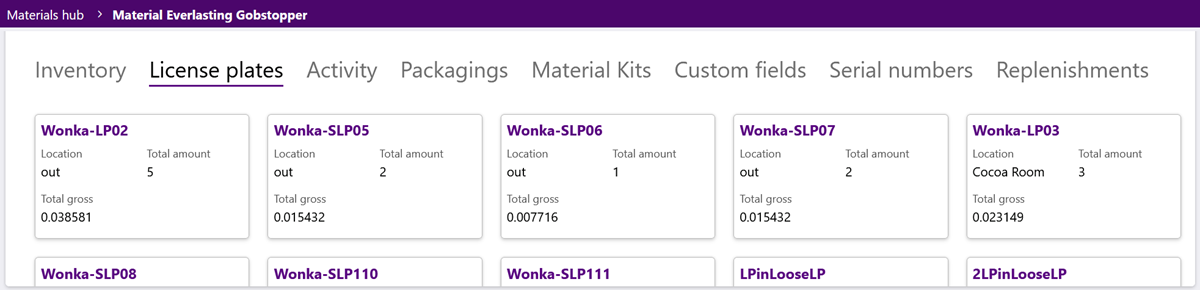

The Material License Plates tab displays all License Plates associated with the Material. Users can click the LP to open it for review and management.

Material License Plates Tab Details

| License Plate: | The License Plate number the Material is assigned to. |

| Location: | The physical Location of the Material in the Warehouse. |

| Total Amount: | The total amount of the Material in the License Plate. |

| Total Gross: | The total weight of the Material, including the Packaging. |

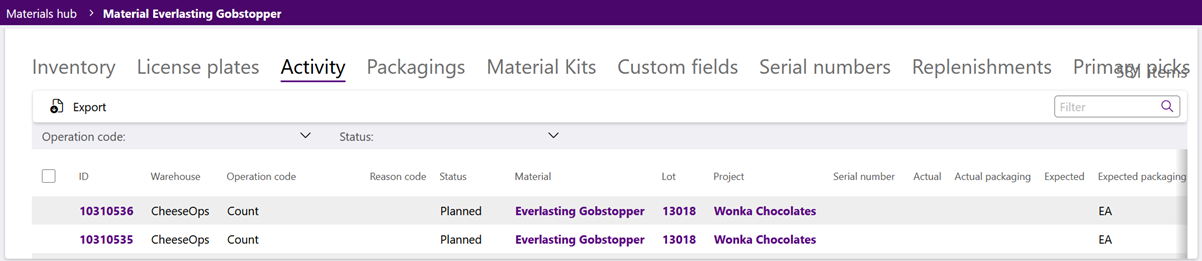

The Material Activity tab lists all Activities associated with the Material. When viewing Material Activity, users can filter Activity by Operation Code and Status. Selecting a row or multiple rows allows users to Export the selected details to an Excel spreadsheet.

Material Activity Tab Details

| ID: | The Activity ID for the Material Activity. |

| Warehouse: | The Warehouse in which the Material Activity took place. |

| Operation Code: | The Operation Code for the Material Activity. |

| Reason Code: | The Reason Code for the Material Activity. |

| Status: | The Status of the Material Activity. |

| Material: | The name of the Material. |

| Lot: | The Lot the Material involved in the Activity is part of. |

| Project: | The Project the Material is part of. |

| Serial Number: | The Serial number of the Material involved in the Activity. |

| Actual: | The actual amount of the Material involved in the Activity. |

| Actual Packaging: | The actual Packaging of the Material involved in the Activity. |

| Expected: | The expected amount of the Material involved in the Activity. |

| Expected Packaging: | The expected Packaging of the Material involved in the Activity. |

| Order: | The Order number associated with the Activity. |

| Created Date: | The date the Activity was created. |

| Completed Date: | The date the Activity was completed. |

| User: | The User that completed the Activity. |

| Actual Source LP: | The actual Source License Plate number involved in the Activity. |

| Actual Source Loc: | The actual physical Source Location involved in the Activity. |

| Actual Target LP: | The actual Target License Plate number involved in the Activity. |

| Actual Target Loc: | The actual physical Target Location involved in the Activity. |

| Expected Source LP: | The expected Source License Plate number involved in the Activity. |

| Expected Source Loc: | The expected physical Source Location involved in the Activity. |

| Expected Target LP: | The expected Target License Plate number involved in the Activity. |

| Expected Target Loc: | The expected physical Target Location involved in the Activity. |

| Order Reference: | The Order Reference number associated with the Activity. |

| Order PO: | The Order PO number associated with the Activity. |

| Notes: | Any Notes associated with the Activity. |

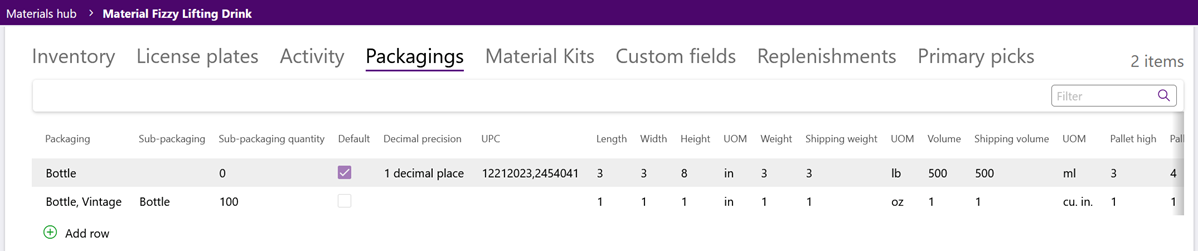

The Material Packagings tab allows for the Material's Packagings to be setup. Any existing Packagings are listed for review and management.

Users can add as many levels of Packaging as are needed.

Note

A Material must have at least one Package level - the Base Package.

If more levels of Packaging are needed, start over by adding another Packaging, and then in the Sub Packaging field, select the Packaging that would go inside the new Packaging. In the Sub Package Qty field, enter the number of smaller Packages it takes to fill the new Packaging level. Continue this way for as many levels deep as are needed.

Material Packagings Tab Details

| Packaging: | The base level Packaging type. |

| Sub-Packaging: | If there is a level of Packaging directly below, select that here. For example, there may be multiple 'Eaches' (an individual unit) inside a Box, several of which go inside a Case. |

| Sub-Packaging Quantity: | The amount of the Sub-Packaging which are able to be contained within the Packaging. |

| Default: | When enabled, this Package level will be the default level for the Material. May be tied to Billing. |

| Decimal Precision: | Allows the Package to be split into fractions. The No Decimals setting does not allow splitting, requiring each Package to be whole; each subsequent setting (1 Decimal Place, 2 Decimal Places, etc.), allow division up to the specified decimal place. For example, the Package "Gallon" with the setting of 3 Decimal Places could have an inventory of 3.672 Gallons. |

| UPC: | Universal Product Code, unique to each level of Packaging. Multiple UPC Codes can be entered here, each separated by a comma. |

| Length: | Length of Package. |

| Width: | Width of Package. |

| Height: | Height of Package. |

| UOM: | Unit of measurement for distance. Options include meter, centimeter, foot, and inch. |

| Weight: | Weight of the items in this Package. |

| Shipping Weight: | Weight of the items in this Package, combined with the weight of the Package itself (Tare Weight). |

| UOM: | Unit of measurement for weight. Options include kilogram, gram, pound, ounce, ton, troy ounce, and metric ton. |

| Volume: | The Volume of the Package. Footprint automatically computes a volume based on the length width and height, which is displayed underneath those measurements. Enter that here. |

| Shipping Volume: | Volume of the Package considering any other factors that may impact the Package before Shipping. |

| UOM: | Unit of measurement for volume. Options include cubic meter, cubic centimeter, cubic foot, and cubic inch. |

| Pallet High: | The number of this Package that can be stacked atop each other on a Pallet. |

| Pallet Tie: | The number of this Package to be placed on the first level of the Pallet before you begin stacking atop them. |

| Shippable Container: | When enabled, this Packaging can be used as an actual Shipping Container, and does not need to be packed further. |

| Autogenerate Serials: | When enabled, Serial Numbers will be automatically generated with a sequential Serial Number when prompted for this Packaging level. |

| Stack Group: | A field for entering a group name for this item when Stacked. Used for Cartonization process. |

*Those in red are required fields.

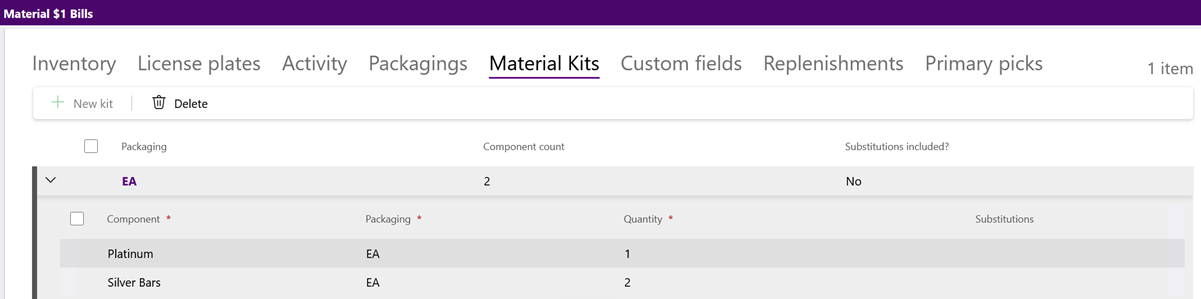

The Material Kits tab displays any Kits for the Material. Options in the Material Kits tab toolbar allow users to create a Material Kit and Delete selected Material Kit(s).

Example

A Table Material Kit may be composed of four Table Leg Materials and one Table Surface Material.

When a Kit exists, users can click the arrow icon to view the Material Kit Components. Users can edit Kit Components by clicking the purple name of the Kit, which opens the Kit Components window for updates.

Material Kits Tab Details

The following details are related to the Material Kit as a whole.

| Packaging: | Each different level of Packaging for the Material can have a different combination of Kit Components. The Components of the selected Packaging Type are shown in the Kit Components pane. |

| Component Count: | The number of component Materials to be included in the kit. |

| Substitutions Included?: | When enabled, allows components in the Kit to be substituted by other specified Materials. |

Material Kits Tab Component Details

The following details are related to the Material Kit Components individually.

*Those in red are required fields.

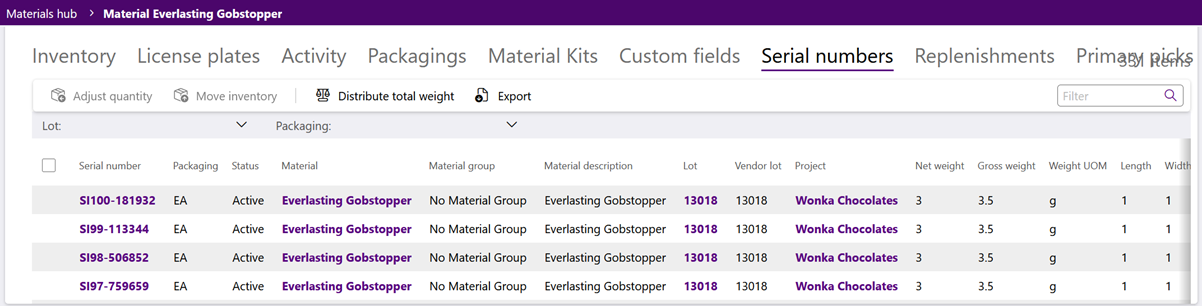

The Material Serial Numbers tab only displays when the Material is Serial Tracked/Controlled. The Material Serial Numbers will be listed for review and management. Users have the option to Adjust Quantity, Move Inventory, and Distribute Total Weight. Selecting a row or multiple rows allows users to Export the selected details to an Excel spreadsheet. Users can also filter the Serial Materials by Lot and Packaging.

Material Serial Numbers Tab Details

| Serial Number: | The unique Serial number assigned to the Material item. |

| Packaging: | The Packaging Type of the Material. |

| Status: | The Status of the Serial Material. |

| Material: | The name of the Material. |

| Material Group: | The Material Group associated with the Material. |

| Material Description: | A short description of the Material. |

| Lot: | The Lot the Material is part of. |

| Vendor Lot: | The Vendor Lot the Material belongs to. |

| Project: | The Project the Material is part of. |

| Net Weight: | The Net Weight of the Material. |

| Gross Weight: | The total Gross Weight of the Material, including the Packaging. |

| Weight UOM: | Unit of measurement for weight. |

| Length: | Length of Material. |

| Width: | Width of Material. |

| Height: | Height of Material. |

| Dimension Measure: | Unit of measurement for distance. |

| Net Volume: | The Net Volume of the Material. |

| Gross Volume: | The total Gross Volume of the Material, including the Packaging. |

| Volume UOM: | Unit of measurement for volume. |

| Fixed Dimensions: | Indicates whether or not the Material Dimensions are always fixed. |

| Created Date: | The date the Serial Number was created. |

| Created User: | The User that created the Serial Number. |

| LP Type: | The Type of License Plate the Material is assigned to. |

| LP: | The License Plate number the Material is assigned to. |

| Location: | The physical Location of the Material in the Warehouse. |

| Warehouse: | The Warehouse in which the Material is located. |

| Notes: | Any Notes related to the Serial Material. |

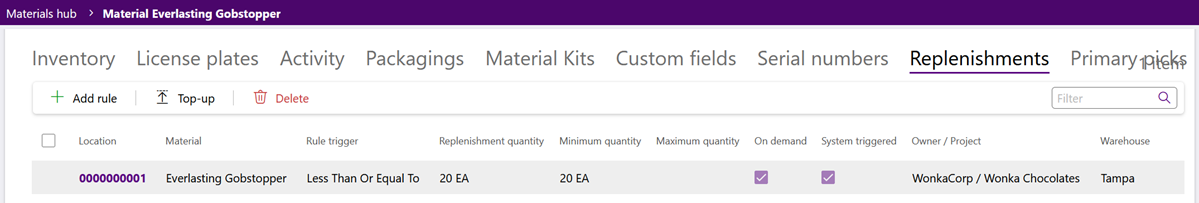

The Material Replenishments tab lists any Replenishments for the Material in the specified Location. The toolbar allows users to Add Rules, Top-Ups, and Delete Replenishment Rules.

Material Replenishments Tab Details

| Location : | The Location of the Replenishment Material. |

| Material: | The name of the Material. |

| Rule Trigger: | The Rule that Triggers the Replenishment. |

| Replenishment Quantity: | The amount of the Material that is Replenished once Triggered. |

| Minimum Quantity: | Once the number of Packages of the Material in the Location drops below this number, a Replenishment Task will be created. |

| Maximum Quantity: | The maximum total of Packages that can be stored for this Material. |

| On Demand: | When enabled Replenishment Tasks will not be created automatically, but the Materials can be Replenished manually as needed. |

| System Triggered: | When enabled, Replenishment Tasks will be automatically created when a Replenishment Event is triggered. |

| Owner / Project: | The Owner and Project of the Replenishment Materials. |

| Warehouse: | The Warehouse where the Replenishment Materials are held. |

*Those in red are required fields.

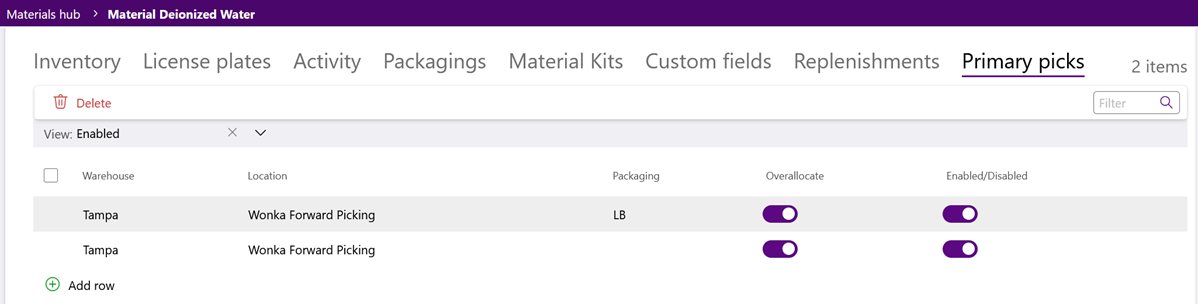

The Material Primary Picks tab lists any designated Primary Pick Locations for the Material. The Delete button in the Primary Pick tab toolbar allows users to delete the selected Material Primary Pick Location(s).

Material Primary Picks Tab Details

| Warehouse: | The Warehouse where the Primary Pick Location for the Material exists. |

| Location: | The Primary Pick Location. |

| Packaging: | The Packaging Type to Primarily Pick from this Location. |

| Overallocate: | When enabled, this allows Over Allocation from this Primary Pick Location. |

| Enabled / Disabled: | When enabled, the Material will use this as a Primary Pick Location. |

| Last Updated: |

| 06/06/2025 |