Sections

Overview

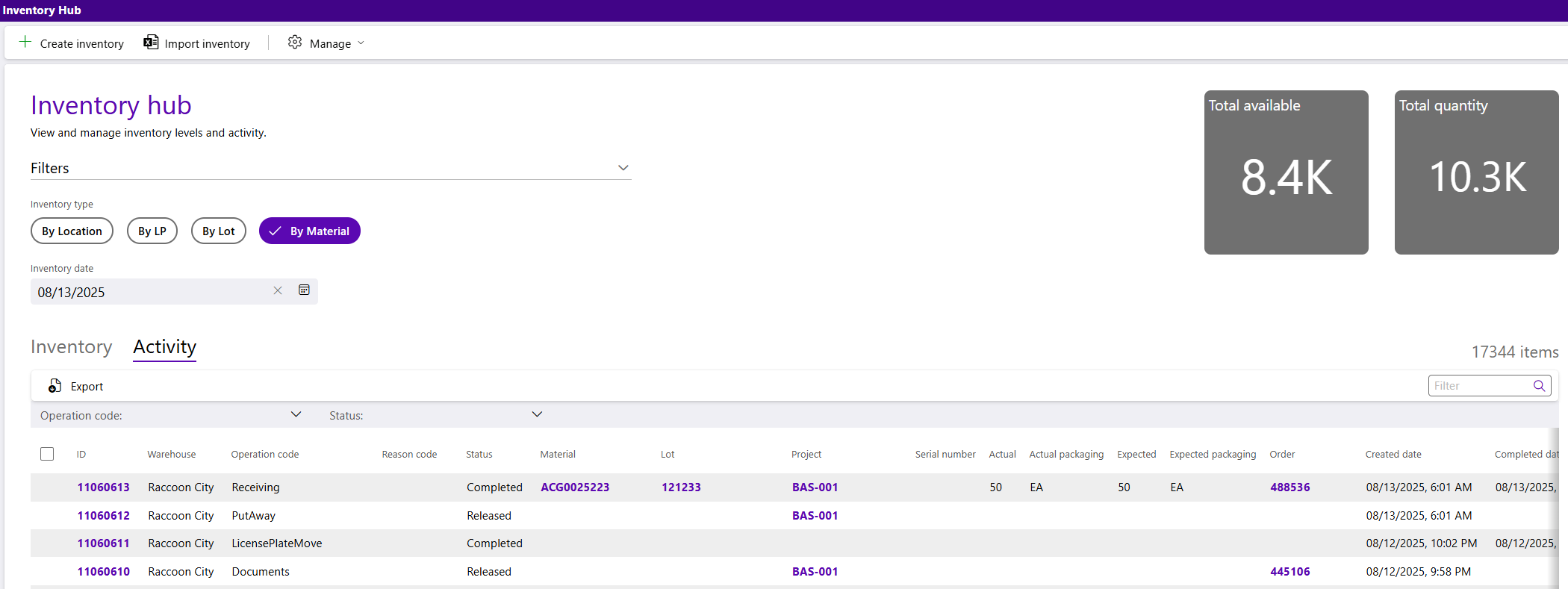

From the Inventory Hub, users can add, review, and manage Inventory and all related actions across Projects and/or Warehouses. Users can also Manage Container Types, Reason Codes, and Inventory Snapshot Rules from the Inventory Hub.

Inventory can be reviewed and managed from several different perspectives, in addition to the Inventory Hub view. These other Inventory Views (submenus) are: Activity, Lots, Serial Numbers, Inventory Transfers, Inventory Counts, Replenishments, and Warehouses.

Inventory Hub

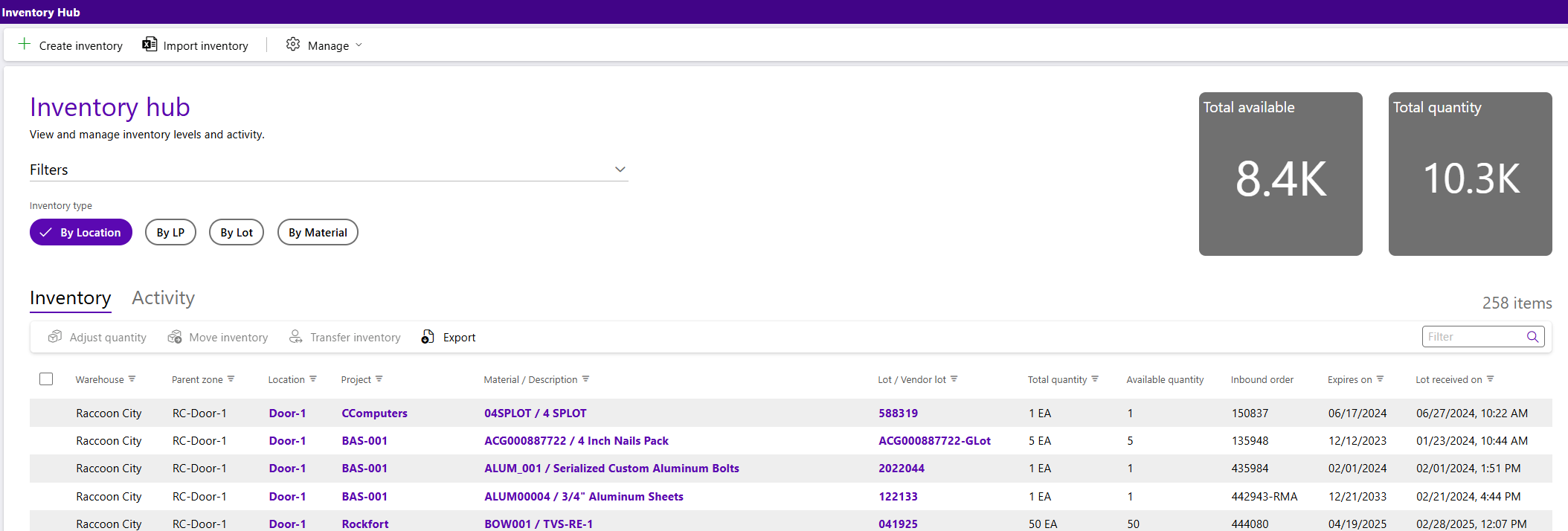

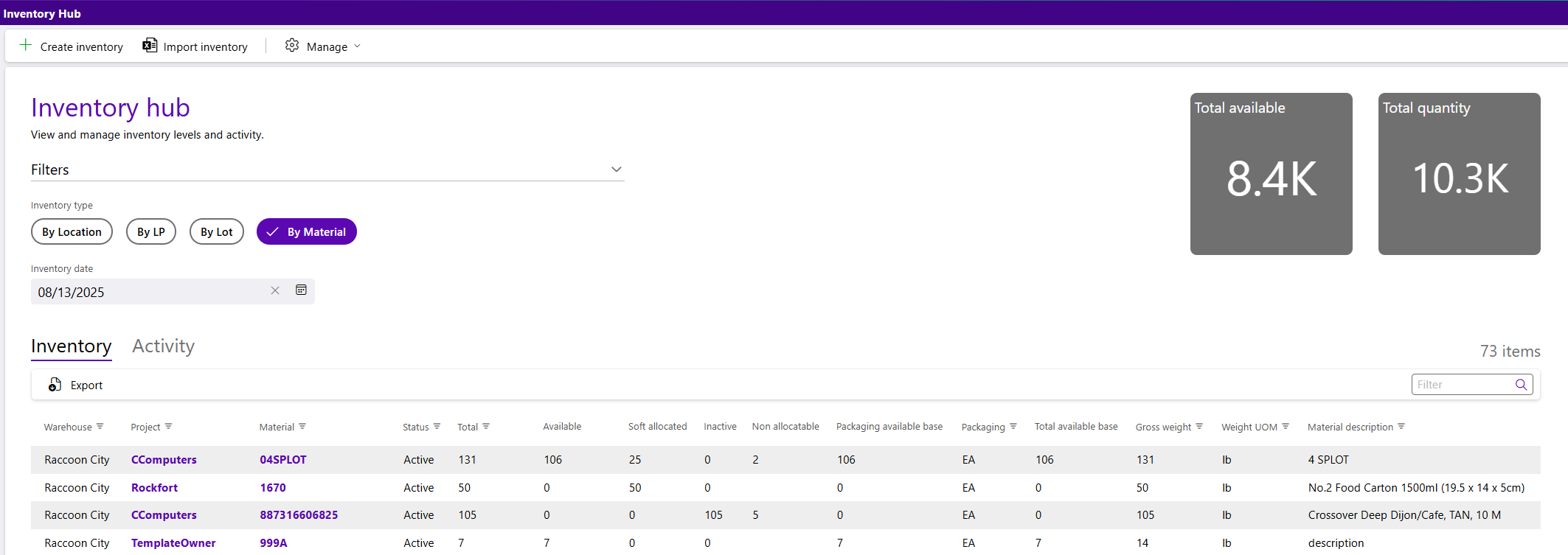

The Inventory Hub allows you to create and import new Inventory, review and manage all existing Inventory, and Manage Container Types, Reason Codes, and Inventory Snapshot Rules. All active Inventory is listed, sorted by Location as the default. In the top, right corner are two tiles indicating the number of Total Available and Total Amount.

Icons along the top of the Inventory Hub allows users to Create or Import new Inventory. Users can also Manage Container Types, Manage Reason Codes, and Manage Inventory Snapshot Rules from the Inventory Hub.

Search and filter options are available to quickly locate Inventory for review and management. Users can filter by Owner, Project, Material, and Warehouse.

Inventory can be sorted by Location, by LP, by Lot, or by Material using the Inventory Types buttons under the Filters.

Inventory displays in the Inventory tab, and Activity displays in the Activity tab. Each tab on the Inventory Hub displays it's own set of information and options for managing that information. Expand the sections below for more details about each tab.

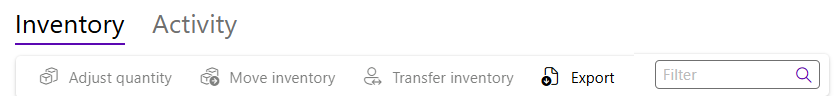

The Inventory tab lists all active Inventory. The Inventory tab toolbar provides options to manage selected Inventory, such as Adjust Inventory, Move Inventory, Transfer Inventory, and Export.

| Warehouse: | The Warehouse in which the Inventory is located. |

| Parent Zone: | The Parent Zone of the Inventory in the Warehouse. |

| Location: | The physical Location of the Inventory in the Warehouse. |

| Project: | The Name of the Project associated with the Inventory. |

| Material: | The Material name for the Inventory. |

| Lot: | The Lot ID of the Inventory. |

| Total Amount: | The total amount of Inventory in the Warehouse. |

| Available Amount: | The available amount of Inventory in the Warehouse. |

| Packaging: | The Packaging UOM of the Inventory. |

| Inbound Order: | The Inbound Order number associated with the Inventory, when applicable. |

| Vendor Lot: | The Vendor Lot ID of the Inventory. |

| Expiration Date: | The expiration date of the Inventory. |

| Manufacture Date: | The manufacture date of the Inventory. |

| Received Date: | The date the Inventory was marked as Received. |

| Material Description: | The Material description for the Inventory. |

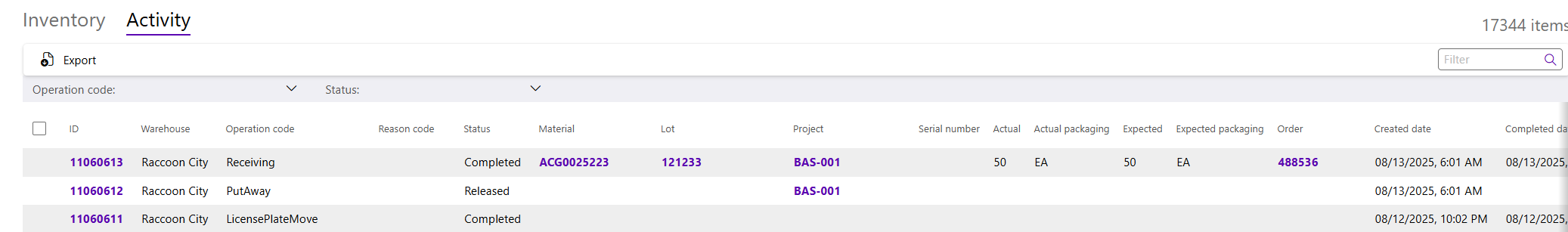

The Activity tab displays Activity for Inventory, along with the option to Export the details of the selected Activity.

| ID: | The unique Activity ID for the Inventory Activity. |

| Warehouse: | The Warehouse in which the Inventory Activity is taking place. |

|

Operation Code: |

The Operation Code of the Inventory Activity. |

| Status: | The Status of the Inventory Activity. |

| Material: | The Material name associated with the Inventory Activity. |

| Lot: | The Lot ID associated with the Inventory Activity. |

| Project: | The Name of the Project associated with the Inventory Activity. |

| Serial Number: | The Serial Number associated with the Inventory Activity. |

| Actual: | The actual amount of Inventory associated with the Task. |

| Actual Packaging: | The Packaging Type used for the Task. |

| Expected: | The expected amount of Inventory associated with the Task. |

| Expected Packaging: | The expected Packaging Type used for the Task. |

| Order: | The Order number associated with the Inventory Activity. |

| Created Date: | The Created date of the Inventory Activity. |

| Completed Date: | The Completed date of the Inventory Activity. |

| User: | The logged in user that completed the Inventory Activity. |

| Actual Source LP: | The actual Source License Plate associated with the Inventory Activity. |

| Actual Source Location: | The actual Source Location associated with the Inventory Activity. |

| Actual Target LP: | The actual Target License Plate associated with the Inventory Activity. |

| Actual Target Location: | The actual Target Location associated with the Inventory Activity. |

| Expected Source LP: | The expected Source License Plate associated with the Inventory Activity. |

| Expected Source Location: | The expected Source Location associated with the Inventory Activity. |

| Expected Target LP: | The expected Target License Plate associated with the Inventory Activity. |

| Expected Target Location: | The expected Target Location associated with the Inventory Activity. |

| Order Reference: | The Order Reference number associated with the Inventory Activity. |

| Order PO: | The Purchase Order number associated with the Inventory Activity. |

| Notes: | Any Notes entered for the Inventory Activity. |

Inventory Views

As previously mentioned, Inventory can be reviewed and managed from several different perspectives, in addition to the Inventory Hub view. Click to expand each section below to learn more about these other Inventory Views (submenus) and the Inventory management options they offer.

The Activity Hub contains details about all Tasks, ranging from the Inventory involved in the Task to the employee who is associated with it. Activity can be filtered by Owner, Project, Warehouse, Operation Codes, and Statuses, as well as Exported. In the Activity tab toolbar, the records can be further filtered by Dates.

Footprint is a Task-based system, which means all Activity is tracked. Every action from Receiving Inventory to changing a Status to Completing an Order, is represented by a Task. These individual Tasks carry a wealth of information about the operation being performed, along with a Status for the Task itself.

| ID: | The unique Activity ID for the Inventory Activity. |

| Warehouse: | The Warehouse in which the Inventory Activity is taking place. |

|

Operation Code: |

The Operation Code of the Inventory Activity. |

| Status: | The Status of the Inventory Activity. |

| Material: | The Material name associated with the Inventory Activity. |

| Lot: | The Lot ID associated with the Inventory Activity. |

| Project: | The Name of the Project associated with the Inventory Activity. |

| Serial Number: | The Serial Number associated with the Inventory Activity. |

| Actual: | The actual amount of Inventory associated with the Task. |

| Actual Packaging: | The Packaging Type used for the Task. |

| Expected: | The expected amount of Inventory associated with the Task. |

| Expected Packaging: | The expected Packaging Type used for the Task. |

| Order: | The Order number associated with the Inventory Activity. |

| Created Date: | The Created date of the Inventory Activity. |

| Completed Date: | The Completed date of the Inventory Activity. |

| User: | The logged in user that completed the Inventory Activity. |

| Actual Source LP: | The actual Source License Plate associated with the Inventory Activity. |

| Actual Source Location: | The actual Source Location associated with the Inventory Activity. |

| Actual Target LP: | The actual Target License Plate associated with the Inventory Activity. |

| Actual Target Location: | The actual Target Location associated with the Inventory Activity. |

| Expected Source LP: | The expected Source License Plate associated with the Inventory Activity. |

| Expected Source Location: | The expected Source Location associated with the Inventory Activity. |

| Expected Target LP: | The expected Target License Plate associated with the Inventory Activity. |

| Expected Target Location: | The expected Target Location associated with the Inventory Activity. |

| Order Reference: | The Order Reference number associated with the Inventory Activity. |

| Order PO: | The Purchase Order number associated with the Inventory Activity. |

| Notes: | Any Notes entered for the Inventory Activity. |

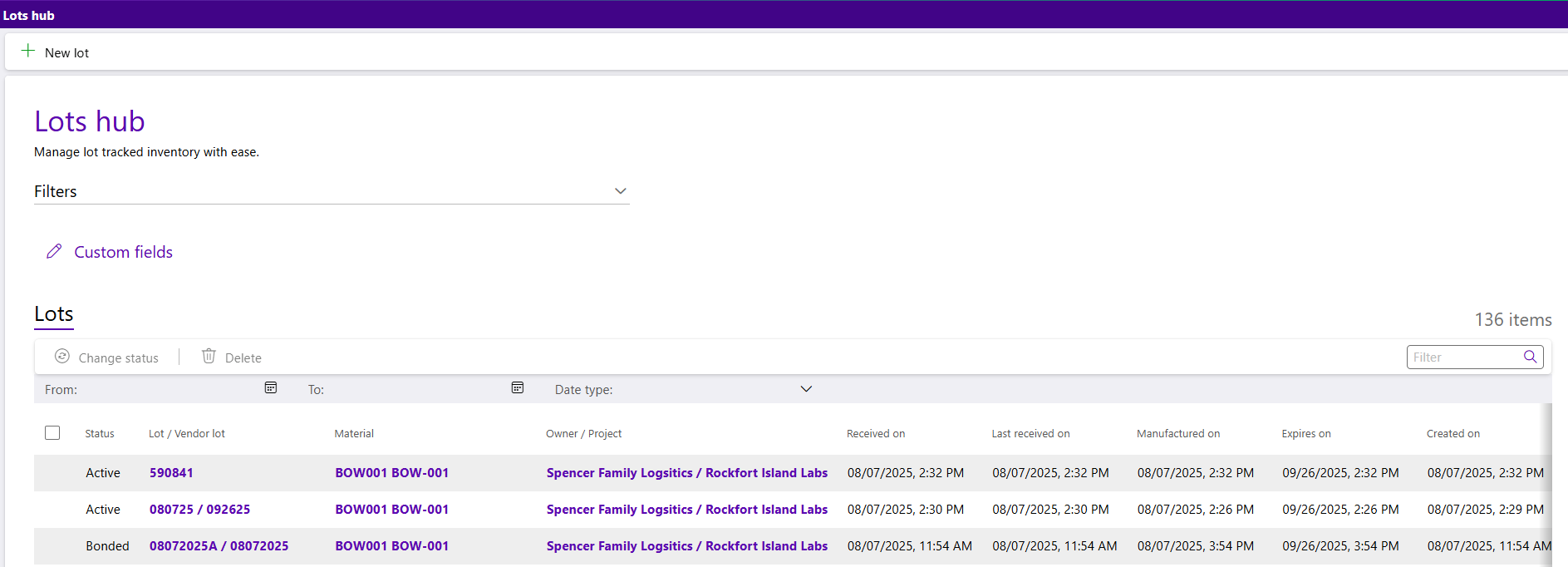

The Lots Hub displays all the Lots associated with the Inventory. When Inventory is Lot Controlled (its Control Type is either Lots or LotsSerial), unique Lots and Vendor Lots for each Material of that type are tracked. Lots can be filtered by Owner, Project, Materials, and Statuses. In the Lots tab toolbar, the records can be further filtered by Dates.

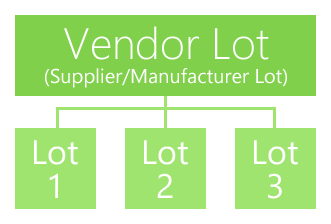

Vendor Lots

Vendor Lots represent the vendor-assigned identification of a particular group of Materials, all sharing the same Manufacturing and Expiration Dates.

Lots

Lots are sub-divisions of Vendor Lots, which share the same information as provided by their parent Vendor Lot, but have an additional Description and Notes. Each Vendor Lot must have at least one Lot.

Lot Controlled Materials are grouped together under Vendor Lots and Lots. For example, Swiss Cheese Inventory could be under the 03/15 Vendor Lot, and further under the 03/21 Lot. This allows you to tell apart the batch of Swiss cheese manufactured on 03/15 from the rest of the Swiss cheese in the Warehouse, as well as the specific portion of that batch that was received on 03/21.

GLots

Inventory that is not Lot Controlled (with a Control Type of either MaterialLot or MaterialLotSerial) is assigned a Generic Lot, or GLot. Each unit of the Material will automatically be assigned this as their Lot and Vendor Lot, eliminating the need to enter any information in these fields.

| Material: | The LookUp Code for the Material belonging to the Lot. |

| Lot/Vendor Lot: | The Lot LookUp and, when applicable, the Vendor LookUp. |

| Status: | The Status of the Lot. |

| Receive Date: | The date and time the Lot was first Received. |

| Last Receive Date: | The date and time the Lot was last Received. |

| Manufactured Date: | The date and time the Lot was Manufactured. |

| Expiration Date: | The date and time the Lot will Expire. |

| Created Date: | The date and time the Lot was created. |

| Modified Date: | The date and time the Lot was last modified. |

| Notes: | Any Notes in the system about the Lot. |

| Owner/Project: | The Owner and Project of the Lot. |

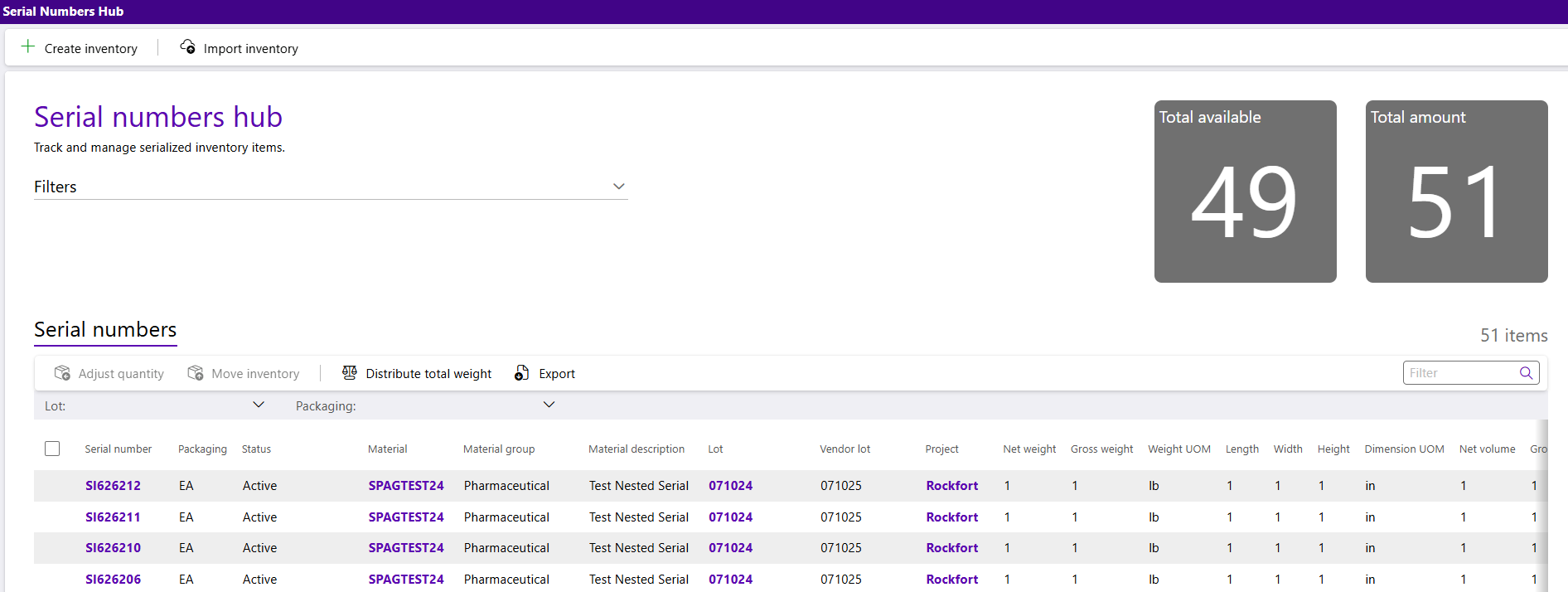

The Serial Numbers Hub displays Inventory by Serial Numbers and can be filtered by Owner, Project, Materials, Warehouses, and Archived status. In the Serial Numbers tab toolbar, the records can be further filtered by Lot and Packaging. Options in the Serial Numbers tab toolbar allow you to Adjust and Move Inventory. In the top, right corner are two tiles indicating the number of Total Available and Total Amount.

Serial Numbers are a way of identifying each individual item of Inventory, rather than remaining anonymous within the Quantity of that type. When Inventory is Serial Controlled (its Control Type is either LotsSerial or MaterialLotSerial), the unique Serial Numbers for each unit of the Inventory of that type is tracked.

More details about individual Inventory can be tied to Serial Numbers in the form of User Defined Fields, which, along with a unique Task History (detailing where the Inventory has been at what time, its past Statuses, and so on) is also kept with the Serial Number.

Serial Numbers are also used to track Variable Weights and Variable Lengths for Materials, so the precise measurement for each Material is recorded. For any item that is not Serial Controlled but uses Variable Weights or Variable Dimensions, the system will automatically create and assign the item a Serial Number to track it by.

| ID: | The system ID for the Serial Number. |

| Serial Number: | The Serial Number's LookUp. |

| Packaging: | The Packaging Type used by the Material for the Serial Number. |

| Status: | The Status of the Serial Number. |

| Material: | The LookUp Code for the Material belonging to the Serial Number. |

| Material Group: | The Material Group for the Material belonging to the Serial Number. |

| Material Description: | A description of the Material belonging to the Serial Number. |

| Lot: | The Name of the Lot the belonging to the Serial Number. |

| Vendor Lot: | The LookUp of the Vendor Lot belonging to the Serial Number. |

| Project: | The Project under which the Serial Numbers are classified. |

| Net Weight: | The Weight of the Serial Number's Material, not including its Packaging. |

| Gross Weight: | The Weight of the Serial Number's Material, including its Packaging. |

| Weight UOM: | The unit by which the Serial Number's Material's weight is measured. |

| Length: | The Length of the Serial Number's Material. |

| Width: | The Width of the Serial Number's Material. |

| Height: | The Height of the Serial Number's Material. |

| Dimension UOM: | The unit by which the Serial Number's Material's dimensions are measured. |

| Net Volume: | The Net Volume of the Serial Number's Material. |

| Gross Volume: | The Gross Volume of the Serial Number's Material. |

| Volume UOM: | The unit by which the Serial Number's Material's volume is measured. |

| Created Date: | The date the Serial Numbers were created. |

| Created User: | The logged in user that created the Serial Numbers. |

| LP Type: | The Type of License Plate on which the Serial Number is located (Inventory or Shipping) |

| LP: | The License Plate on which the Serial Number is located. |

| Location: | The Location in which the Serial Number is located. |

| Warehouse: | The Warehouse in which the Serial Number is located. |

| Notes: | Any Notes in the system about the Serial Number. |

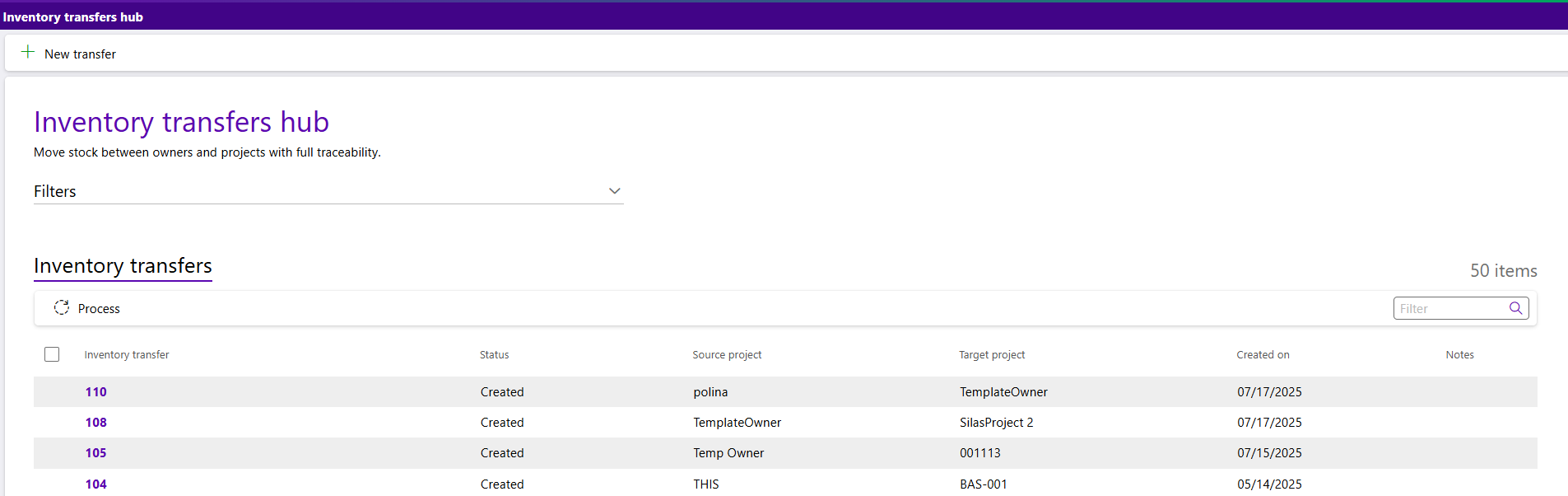

The Inventory Transfers Hub allows users to Transfer Inventory and manage existing Transfers. The Process option in the Transfers tab toolbar allows users to actually Process the Transfer. Inventory Transfers take existing Inventory and either Transfer them to another Owner, or turn them into another Material entirely. Inventory Transfers can be filtered by Warehouses, Source Project, Target Project, and Statuses.

| Transfer Order: | The generated Inventory Transfer LookUp Code, which can be updated by the user. |

| Status: | The current Status of the Inventory Transfer. |

| Source Project: | A drop-down list from which the current Project for the Inventory is selected. |

| Target Project: | A drop-down list from which the new Project for the Inventory is selected. |

| Created Date: | The new Created Date for the Transferred/Transformed Inventory. |

| Notes: | Any Notes entered for the Inventory Transfer. |

*Those in red are required fields.

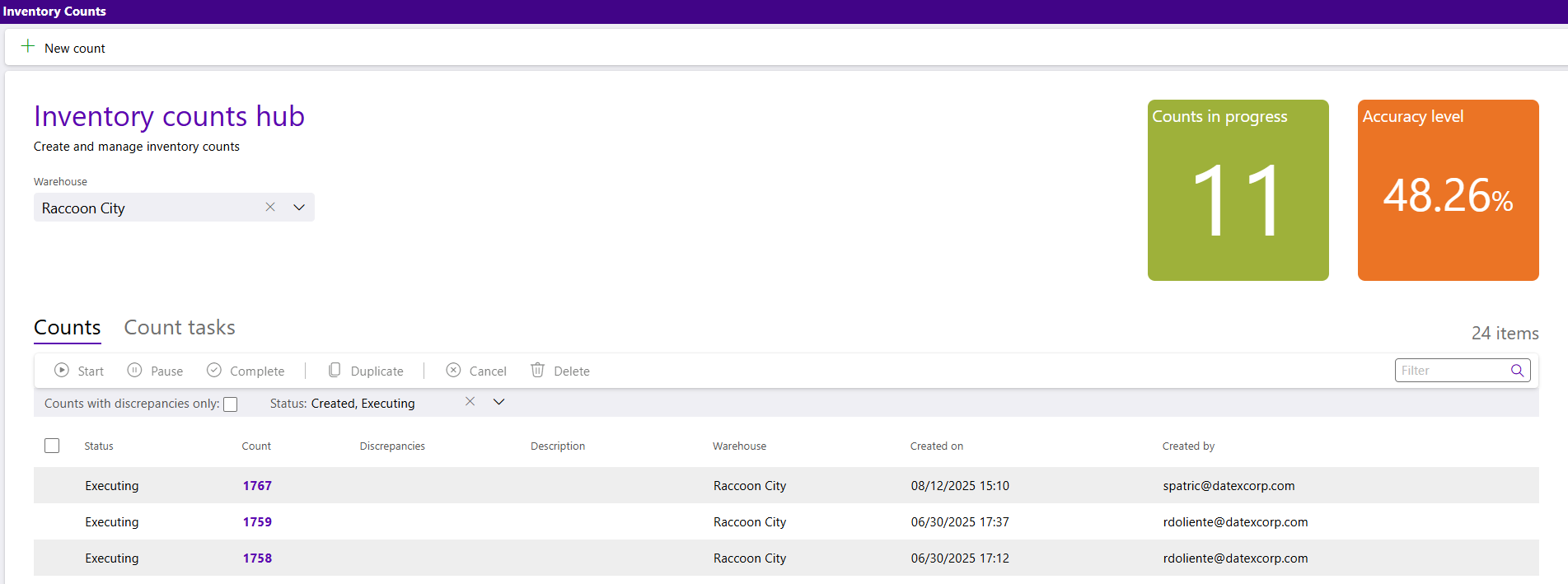

The Inventory Counts Hub allows users to Create an Inventory Count and manage existing Counts using the Start, Pause, Complete, Duplicate, Cancel, and Delete options in the Count tab toolbar. In the top, right corner are two tiles indicating the number of Counts in Progress and the Accuracy Level percentage. Inventory Counts confirm that the Inventory in the physical Warehouse matches the information in Footprint. Counts can be scheduled to automate the process, allowing users to do a Count of what you want, where you want, whenever you want, all while normal operations continue. In the Counts tab toolbar, the records can be further filtered using a Discrepancies Only toggle and Status selector.

Once a Count is released, the child Count Tasks are performed on a mobile device, and must be reviewed and completed in Footprint. The individual Count Tasks created from a Count will be listed for review and management on the Count Tasks tab. Options in the Count Tasks tab toolbar allow users to Resolve Discrepancies, Recount, Cancel, and Override Count Tasks.

Discrepancies occur when a Count Task is performed and License Plate, Material, Lot, Vendor Lot, or Packaging information does not match what is in the system.

| Status: | The current Status of the Inventory Count. |

| Count: | The LookUp for the Inventory Count. |

| Discrepancies: | The number of discrepancies for the Inventory Count, if any. |

| Description: | A description of the Count. |

| Warehouse: | The Warehouse in which the Count is scheduled. |

| Created On: | The Created Date for the Inventory Count. |

| Created By: | The logged in user that created the Inventory Count. |

| Status: | The current Status of the Count Task. |

| Reason: | Any Reason that has been applied to the Count Task. |

| Count Task: | The ID of the Count Task. |

| Project: | The Project for the Count Task. |

| Material: | The Material Counted in the Task. |

| Expected Quantity: | The Quantity of Packaged Inventory Expected to be Counted. |

|

Counted Quantity: |

The Quantity of Packaged Inventory Counted. |

|

Actual Quantity: |

The Quantity of Packaged Inventory Actually Counted. |

| Vendor Lot: | The Vendor Lot of the Inventory Counted in the Task. |

| Lot: | The Lot of the Inventory Counted in the Task. |

| License Plate: | The License Plate of the Inventory Counted in the Task. |

| Warehouse: | The Warehouse in which the Count Task is scheduled. |

| Location: | The Location in which the Count Task is scheduled. |

| Storage Category: | The Storage Category associated with the Count Task. |

| Released On: | The date the Count Task was Released. |

| Counted By: | The logged in user that completed the Count Task. |

| Notes: | Any Notes entered for the Count Task. |

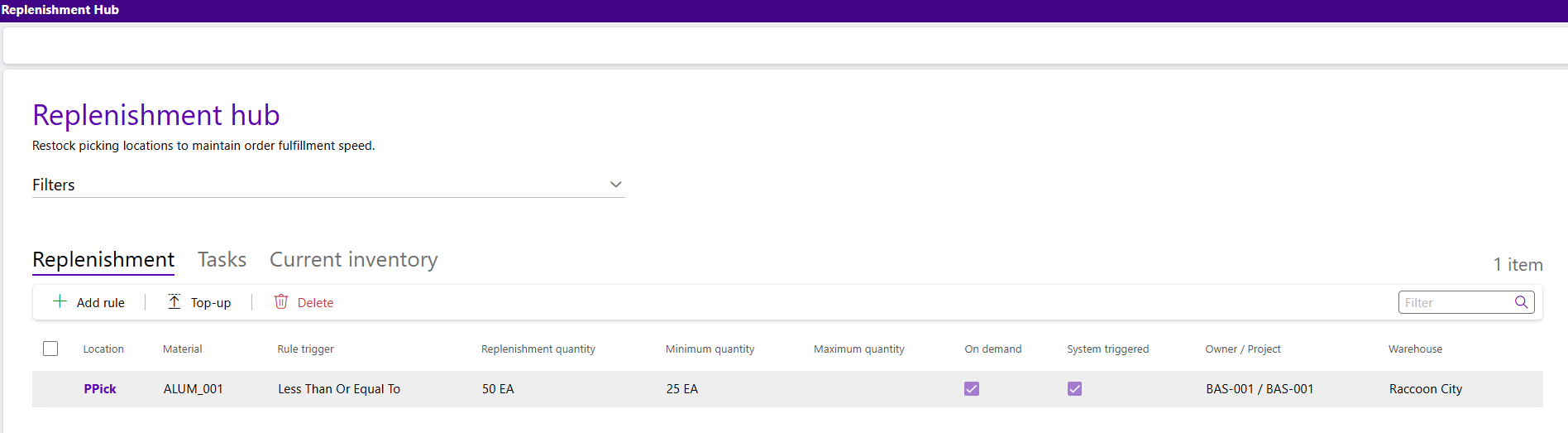

The Replenishment Hub displays all Replenishments for any Inventory in your operation. Replenishments are assigned at the Location level and can be filtered by Owner, Project, Materials, Warehouses, and Locations. From here, users can Add a Replenishment Rule and Add a Top Up.

Each Replenishment listed in the Replenishments tab, when created, generates child Replenishment Tasks listed in the Tasks tab. The Current Inventory tab allows users to quickly Move Inventory for Replenishments as needed.

| Location: | The Location that holds the Replenishment. |

| Material: | The Material for the Replenishment. |

| Rule Trigger: | The Replenishment Rule that will trigger Replenishment Tasks to be automatically created. |

| Minimum Quantity: | Once the number of packaged Inventory in the Location drops below this number, a Replenishment Task will be created. |

| Replenishment Quantity: | The number of packaged Inventory that will be Moved to the Location during standard Replenishment. |

| Maximum Quantity: | The maximum total of packaged Inventory that can be stored. |

| On Demand: | A check box indicating whether or not the Inventory can be Replenished On Demand. |

| System Triggered: | A check box indicating whether or not the Replenishment Tasks for the Replenishment can be automatically created. |

| Owner: | The Owner of the Replenishment Inventory. |

| Project: | The Project under which the Replenishment Inventory is classified. |

| Warehouse: | The Warehouse that holds the Replenishment Inventory. |

| ID: | The system ID for the Replenishment Task. |

| Warehouse: | The Warehouse in which the Replenishment Task is scheduled. |

| Status: | The current Status of the Replenishment Task. |

| Material: | The Material Replenished in the Task. |

| Lot: | The Lot of the Inventory Replenished in the Task. |

| Project: | The Project for the Replenishment Task. |

| Expected: | The Quantity of Packaged Inventory Expected to be Replenished. |

| Expected Packaging: | The Packaging UOM of the Inventory Expected to be Replenished. |

|

Actual: |

The Quantity of Packaged Inventory Actually Replenished. |

|

Actual Packaging: |

The Packaging UOM of Inventory Actually Replenished. |

| Created Date: | The date the Replenishment Task was Created. |

| Expected Target Location: | The Expected Target Location of the Replenishment Task. |

| Expected Target LP: | The Expected Target License Plate for the Replenishment Task. |

| Expected Source Location: | The Expected Source Location of the Replenishment Task. |

| Expected Source LP: | The Expected Source License Plate for the Replenishment Task. |

| Actual Target Location: | The Actual Target Location of the Replenishment Task. |

| Actual Target LP: | The Actual Target License Plate for the Replenishment Task. |

| Actual Source Location: | The Actual Source Location of the Replenishment Task. |

| Actual Source LP: | The Actual Source License Plate for the Replenishment Task. |

| Completed Date: | The date the Replenishment Task was Completed. |

| User: | The logged in user that completed the Replenishment Task. |

| Notes: | Any Notes entered for the Replenishment Task. |

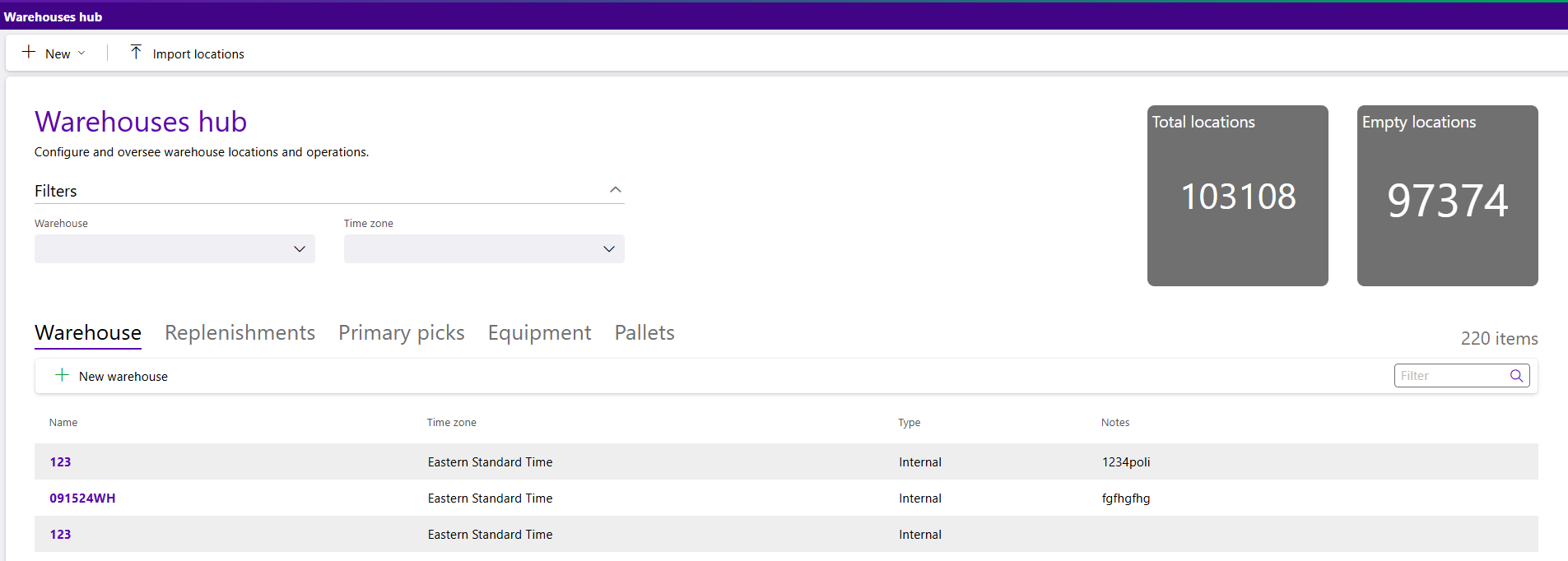

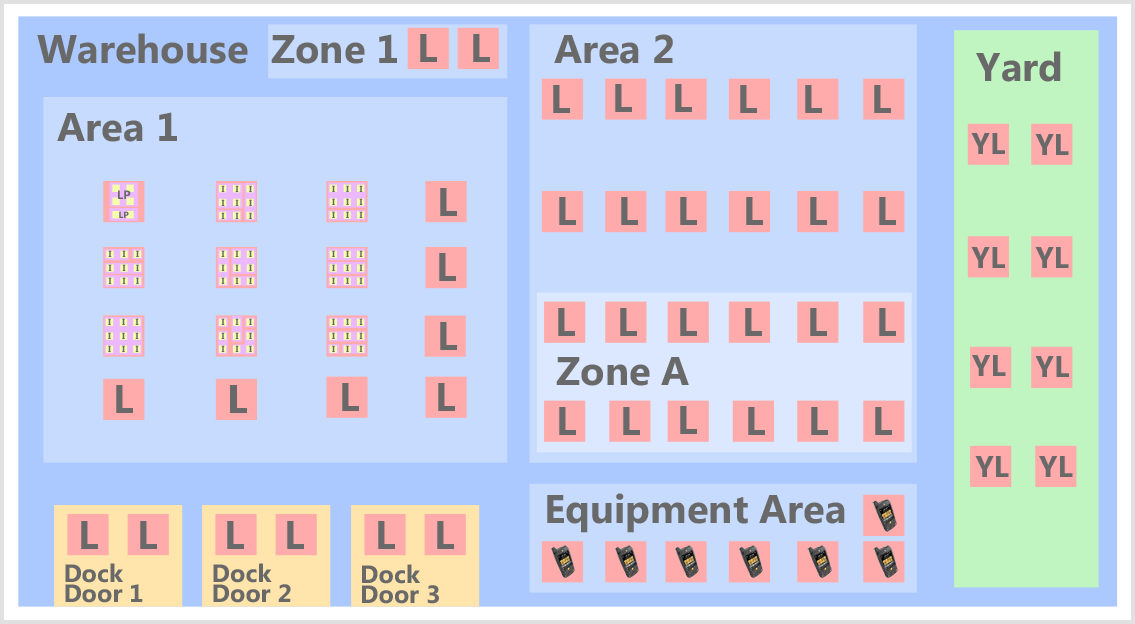

The Warehouses Hub is where you setup and organize each Warehouse, the highest level of the physical storage hierarchy. All Locations, Zones, and Equipment are contained inside a Warehouse and can be managed from the Warehouses Hub. More advanced Location Rules are set here as well, including Storage Categories, Mixing Restrictions, Picking, Packing, and Putaway Sequences, and so on.

The Warehouses Hub can be filtered by Warehouse and Time zone, and provides a broad view of what Inventory is stored in each Location. Using the Warehouses, Replenishments, Equipment, and Pallets tabs, users can Move Inventory, manage Equipment, perform Pallet Transactions, and more. In the top, right corner are two tiles indicating the number of Total Locations and Empty Locations.

Areas and Zones are sections of the Warehouse that can represent rooms, aisles, shelves, etc. They cannot, however, hold Inventory. Areas and Zones instead can contain Locations, which, in turn, hold the Inventory. The only difference between Zones and Areas is that Zones can be assigned Storage Categories and be Enabled or Disabled, while Areas cannot.

Locations are the subsection of the Warehouse that are actually capable of holding Inventory. It is this level that can have License Plates and Inventory assigned to it. Locations can exist on the base level of the Warehouse, but are more commonly contained within Areas or Zones.

A Yard Location is designed to simulate a warehouse yard. It can hold Inventory like a normal Location, but is not intended to be a permanent storage location.

To use mobile devices in the warehouse, the Equipment must first be set up here, in the virtual Warehouse. Equipment Locations function similarly to Locations, in that they can store Inventory, representing the transitional period when moving Inventory from one Location to another.

| Name: | The Name of the Warehouse in Footprint. |

| Time Zone: | The Time Zone of the Warehouse. |

| Type: | The Type of Warehouse. |

| Notes: | Any Notes in the system about the Warehouse. |

| Location: | The Location that holds the Replenishment. |

| Material: | The Material for the Replenishment. |

| Rule Trigger: | The Replenishment Rule that will trigger Replenishment Tasks to be automatically created. |

| Minimum Quantity: | Once the number of packaged Inventory in the Location drops below this number, a Replenishment Task will be created. |

| Replenishment Quantity: | The number of packaged Inventory that will be Moved to the Location during standard Replenishment. |

| Maximum Quantity: | The maximum total of packaged Inventory that can be stored. |

| On Demand: | A check box indicating whether or not the Inventory can be Replenished On Demand. |

| System Triggered: | A check box indicating whether or not the Replenishment Tasks for the Replenishment can be automatically created. |

| Owner: | The Owner of the Replenishment Inventory. |

| Project: | The Project under which the Replenishment Inventory is classified. |

| Warehouse: | The Warehouse that holds the Replenishment Inventory. |

| Device ID: | The ID of the Equipment. |

| Type: | The Type of Equipment. |

| MAC Address: | The MAC Address of the Equipment. |

| Warehouses: | The Warehouse(s) in which the Equipment can be used. |

| Pallet Class: | The name of the Pallet Class for the Pallets. |

| Amount: | The number of Pallets belonging to the Pallet Class. |

| Associated Projects: | The Project(s) associated with the Pallets. |

| Last Updated: |

| 06/06/2025 |