Workflow Types

Workflows can be called at different times and under different circumstances during the normal operation of Footprint. A Workflow's type determines when it can be called, and what inputs and outputs can be used.

For information about customizing Workflows in Footprint, see the Workflow guide.

Inventory Status Change Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

InspectionTaskRelease InspectionTaskConfirmation |

|

InputInspectionTask |

In |

InspectionTask |

|

|

OutputInventoryStatusChangeRequest |

Out |

InventoryStatusChangeRequest |

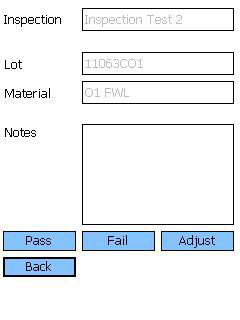

This workflow is called when the Inspection Request workflow is call automatically where it issued a Inventory Status Change Request activity. When it is done this way the input context is InspectionTaskReleased. During this time this workflow can apply any desired activity the end-user has designed such as inventory status changes from Active to on Hold. It can also apply reason codes to this status change. The second time this workflow is called is from the Mobile Inspection Screen whenever the Pass or Fail buttons are clicked.

Inspection Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

ReceivingTaskConfirmation FinishedGoodCreatedTaskConfirmation |

|

InputTask |

In |

Task |

|

|

OutputInspectionRequest |

Out |

InspectionRequest |

|

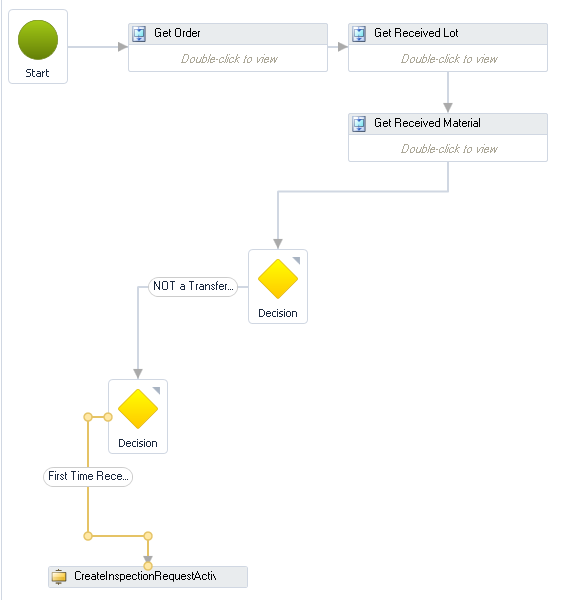

This workflow is called automatically by FootPrint when a receiving operation is performed on the desktop or Mobile. It is also called automatically when a Manufacturing order creates a finished good from the feedback operation. This input context is provide such that end-user can design specific paths in the workflow. The function of this workflow is to allow the deterministic generation of an inspection Task (using the CreateInspectionRequestActivity function.) The inspection task is a specific task that then uses the Inventory Status Change Request to resolve the outcome based on user input from the Mobile’s inspection screen user interface.

This example shows a deterministic workflow that first compares the order class of the inbound and if it is correct type, it then proceeds to check if this is the very first time the lot has been received. If these conditions are met then the CreateInspectionRequestActivity is called. Here this workflow does not consider the InputContext parameter but considers the order class. Manufacturing orders can be handle this way. With workflows there are infinite ways to develop them based upon one’s needs. The activities used in this workflow are:

- CreateInspectionRequestActivity

- FlowDecision

- GetOrdersActivity

- GetLotsActivity

- GetMaterialsActivity

Blind Receive

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

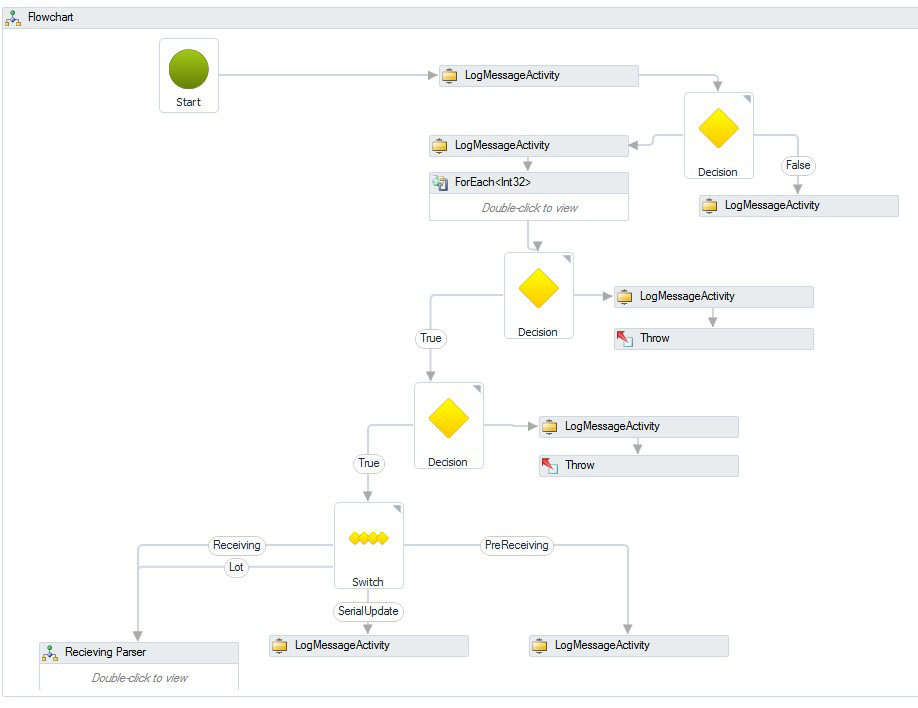

InputContext |

In |

String |

This is provided by FootPrInt32 user Int32erface and details. The value is either { "BlindReceiving", “BlindBarcodeReceiving”} |

|

InputRequest |

In |

BlindReceivingRequest |

This is the receiving task details. |

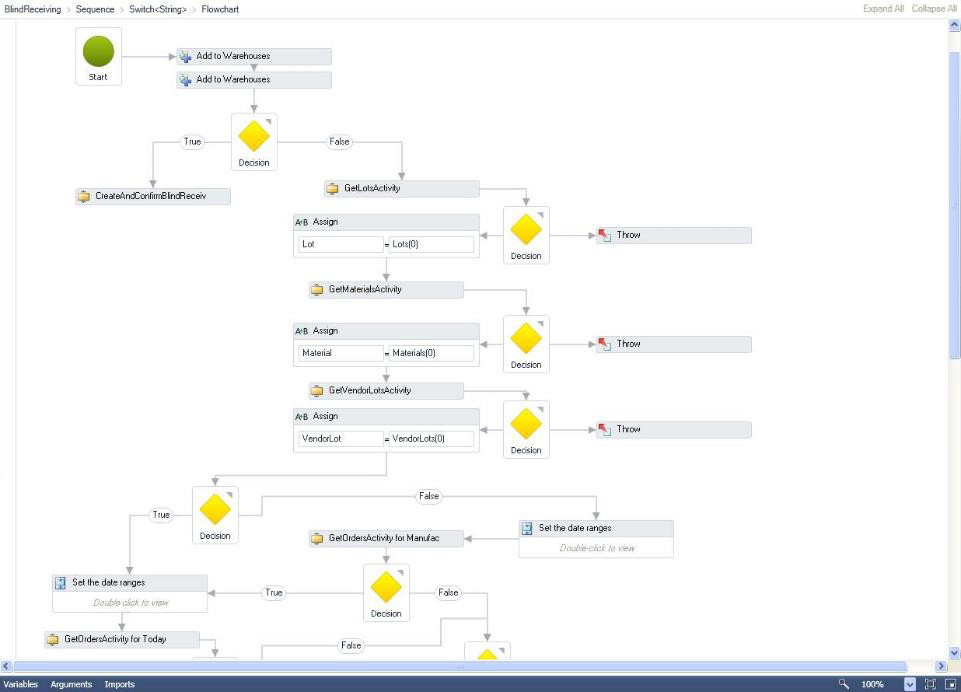

This workflow is called by request in Blind receiving or blind receiving using barcodes. The objective of this workflow is to allow the user to automatically find a order and shipment to add this receiving task to. Also one can use this workflow to create a new order and shipment if it cannot find the appropriate order.

License Plate Moved

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputLicensePlate |

In |

LicensePlate |

|

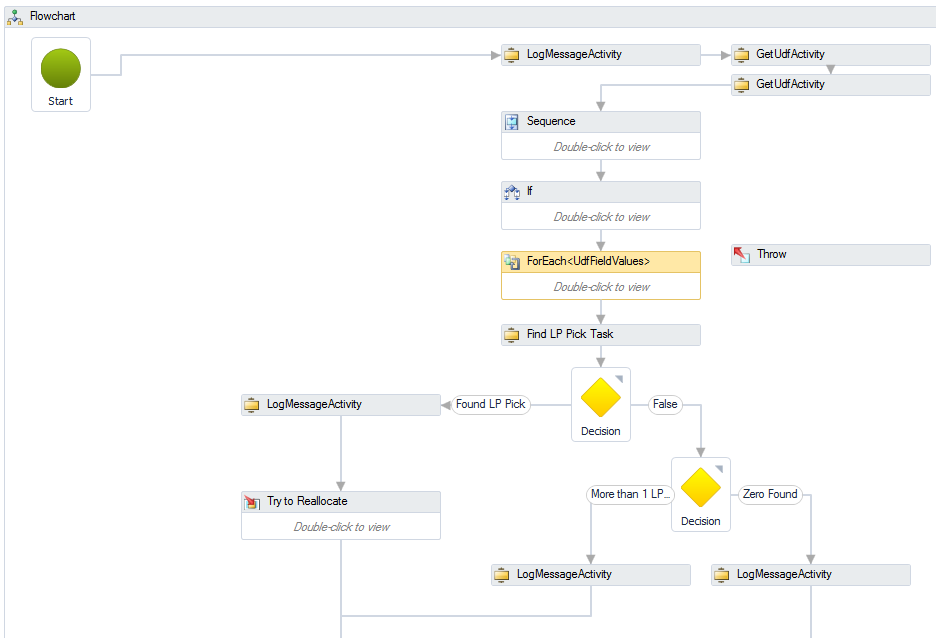

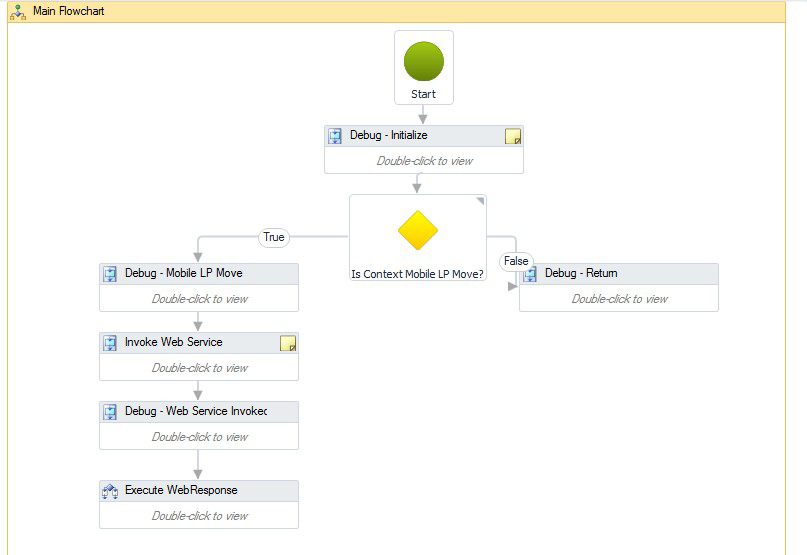

This Workflow is triggered whenever the license plate has moved. Therefore it can be used to find pick task associated to this license plate and attempt to system reallocate them to the new moved location drop. Or one could use this workflow to create accessorial charge tasks as a result of a move for say a special handling charge.

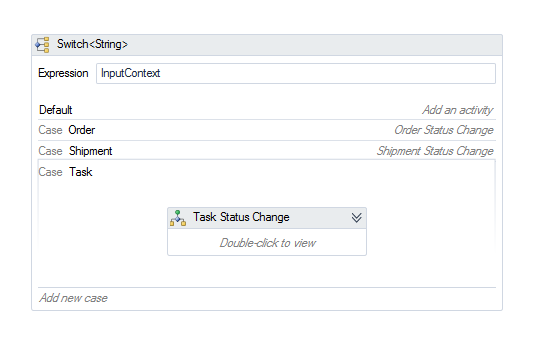

Entity Status Change

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

Order Shipment Task |

|

InputEntityStatusChangeInfo |

In |

EntityStatusChangeInfoBase |

|

This Workflow is triggered whenever the order, shipment, or task status is changed. It is one of the most useful and important workflows in footprint . It can be used to addition tasks, accessorial charges, and so on during a close of a shipment or order. It can be also used to prevent a close of a shipment based on information or details that are missing, for instance a temperature reading on a License plate. It can be used to prevent or supplement moves of inventory or LPs as well. In fact in the Task change all number of combinations can be applied as most operations in footprint are task based. As one task is completed the workflow can be used to create new cascaded tasks. An example of this is as a putaway to a staging area is completed, a new chained putaway can be created and release to complete the move.

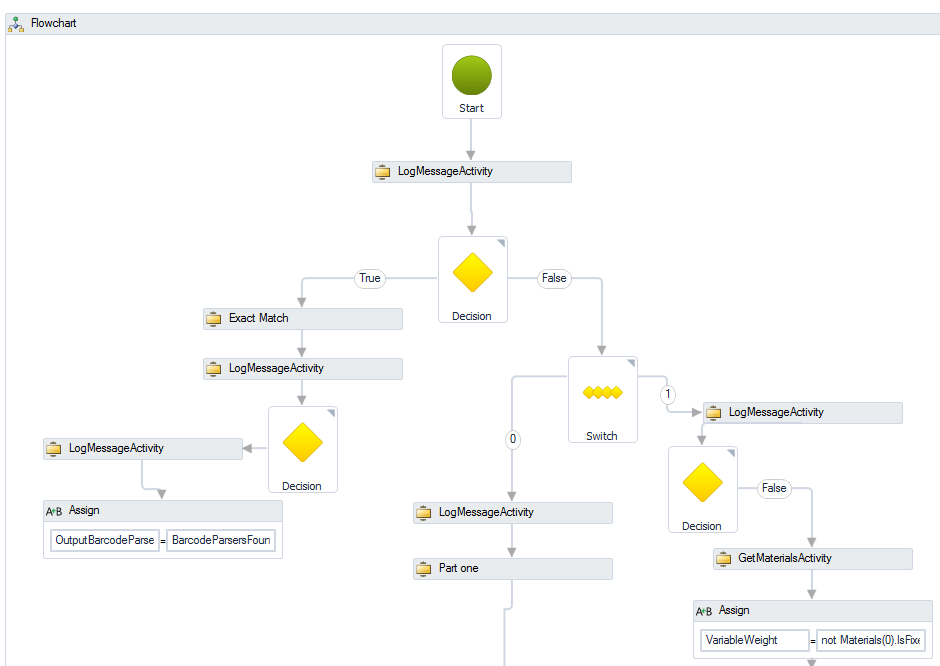

Barcode Parser

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

BarcodeParserContextEnum |

|

|

InputBarcodeParser |

In |

Barcode Parser |

|

|

InputBarcodeString |

In |

String |

|

|

OutputBarcode |

Out |

Barcode |

|

This workflow given an Input string considered to be a barcode scanned from source and the context which is the calling screen and area can be designed to break and parse the string into the output barcode properties. Essentially one is using string function to break it into material names, lot details, serial numbers or ant thing supported in the returning object

Get Barcode Parser

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

Receiving PreReceiving |

|

InputOwnerId |

In |

?int32 |

|

|

InputAccountId |

In |

?int32 |

|

|

InputProjectId |

In |

?int32 |

|

|

InputBarcode |

In |

Barcode |

|

|

InputBarcodeSequence |

In |

int32 |

|

|

OutputBarcodeParser |

Out |

BarcodeParser |

|

This workflow’s objective is to get a parsing definition given input such as the owner and project or account or even the scanned string itself. It is expected to return the definition which is defined under Settingsà ConfigurationsàBarcode Definitions.

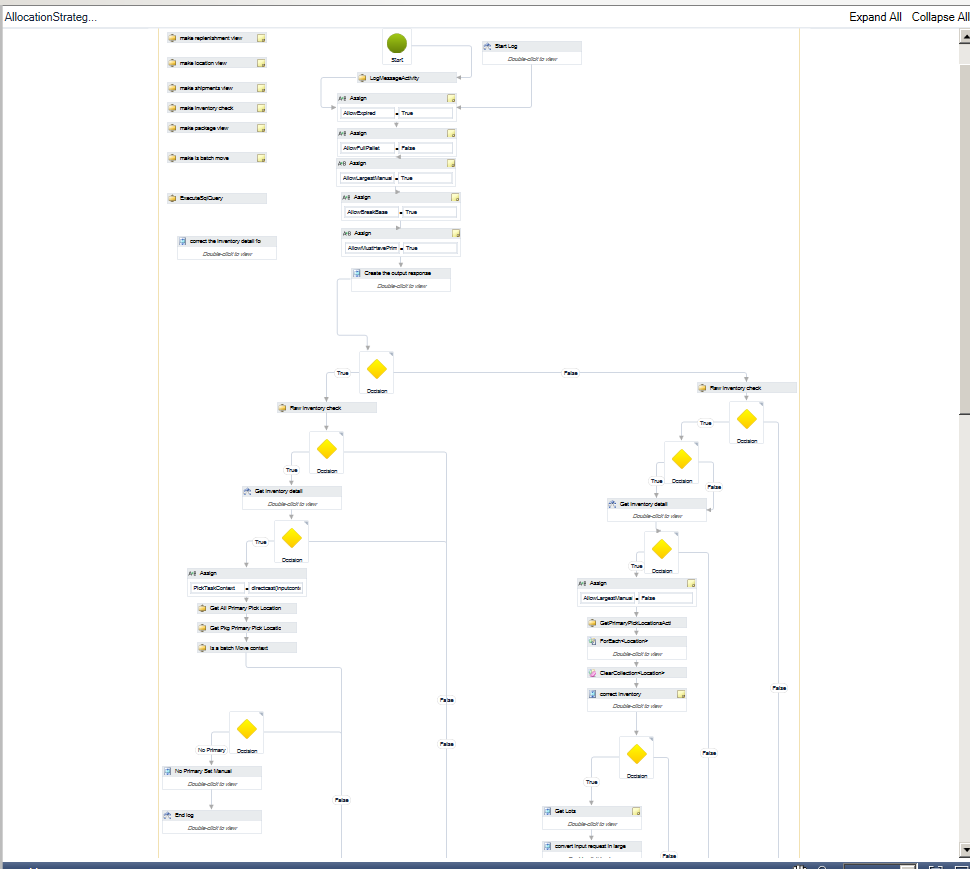

Allocation Strategy

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

HardAllocationContext |

|

|

InputRequest |

In |

HardAllocationRequest |

|

|

OutputResponse |

Out |

HardAlloactionResponse |

|

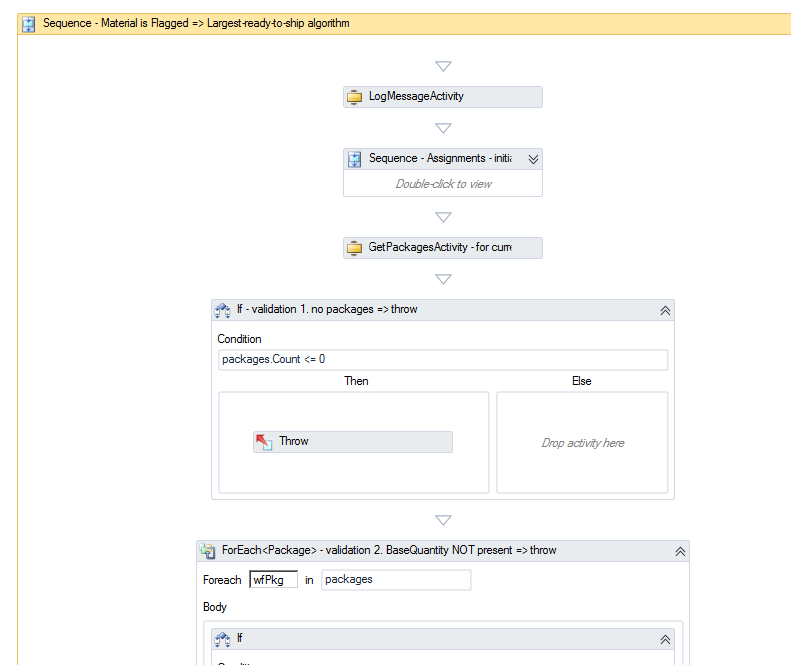

This Workflow is at the heart of FootPrint that give flexiability to how and where a material is being allocated. Given the material, quantity and the package this workflow’s job is to return a list of responses of lots, and locations where the user should pick from. Anything is possible in this workflow when allocating. The workflow has an input of context to allow an ability to allocate differently under for instance outbound orders verse replenishment to forward pick faces. Easily the most complex of workflows

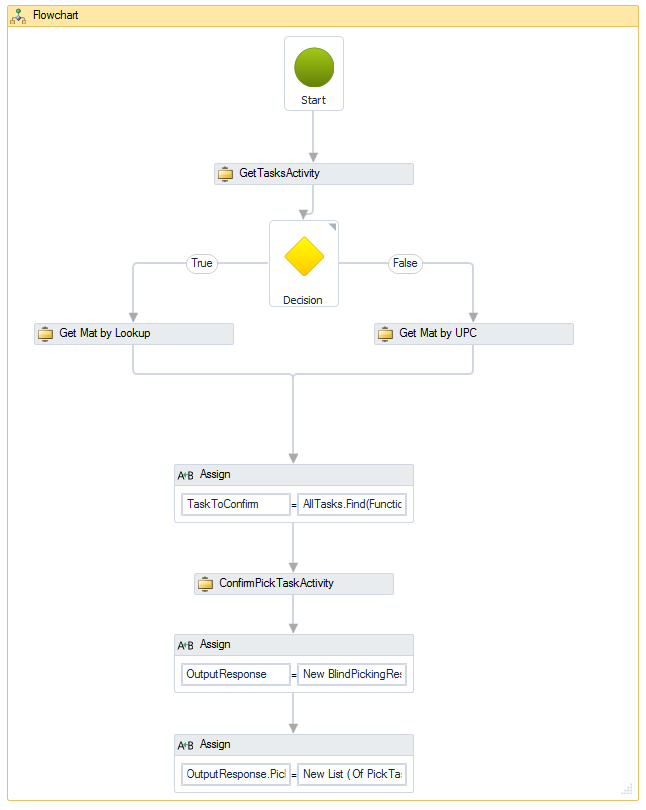

Blind Picking

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputRequest |

In |

BlindPickingRequest |

|

|

OutputResponse |

Out |

BlindPickingResponse |

|

|

AllTasks |

In |

List<Task> |

|

This workflow is triggered to perform a blind picking. Given a list of task and context, the goal of this work is to confirm the picking tasks that are grouped together basis on inputted requests properties. As an example consider we have a rack full of coats and scan the label and transfer to a shipping container. This workflow will find and complete the pick tasks for the order

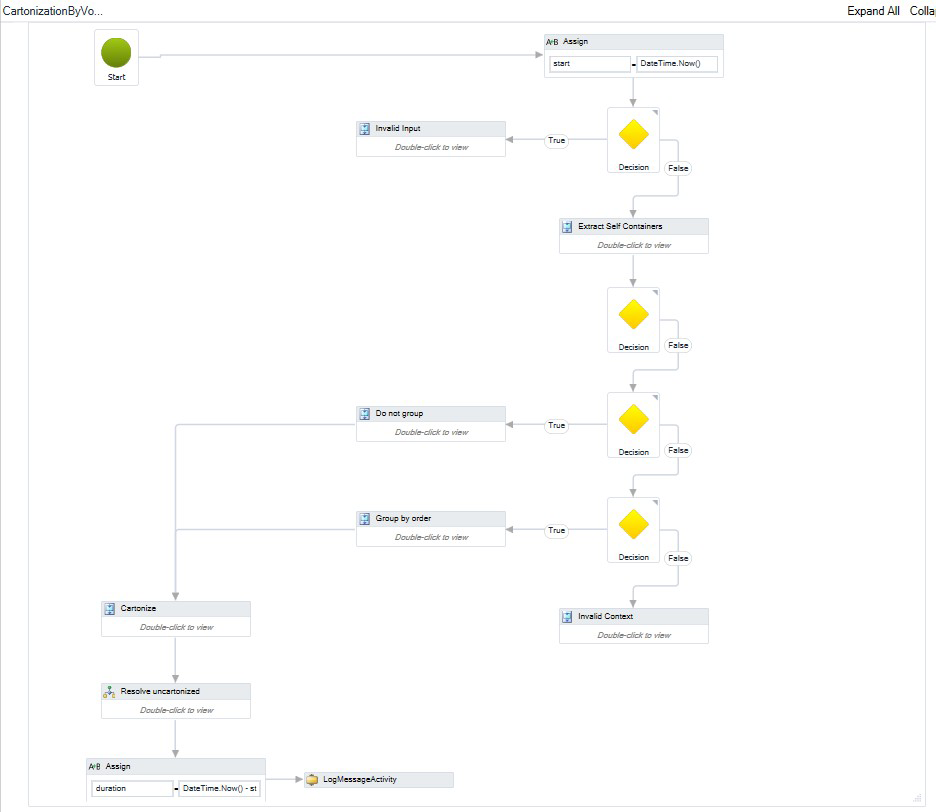

Cartonize

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputCartonizationRequest |

In |

CartonizationRequest |

|

|

OutputCartionizationResult |

Out |

CartonizationResult |

|

When processing an outbound order and there is a need for the system to divide the materials and quantities into the best or least amount of boxes then this is your workflow. Given the materials and quantities then this workflow will return a list of boxes and types with the fill amount of each. FootPrint then creates the output shipment lines and shipping containers directed by this workflow in order to direct user to pick into specific shipping boxes.

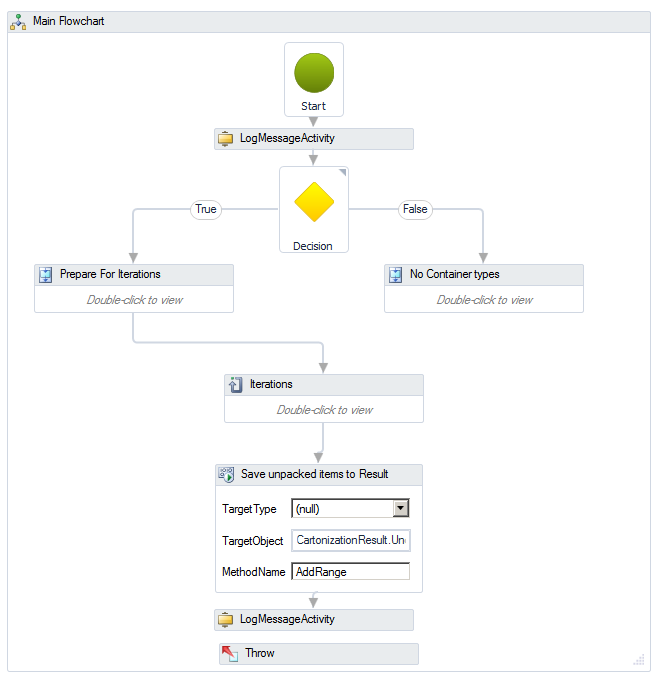

Cartonize Strategy

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

CartonizationQuantities |

In |

List<RawCartonizationQuantity> |

|

|

CartonizationResult |

Out |

RawCartonizationResult |

|

|

CartonizationContainerTypes |

In |

List<RawCartonizationContainerType> |

This is a helper workflow to be used by the main cartonize workflow shown above. It is given raw data like sizes of boxes and materials and can be used to organize the logic and math use when calculating the fitting rules.

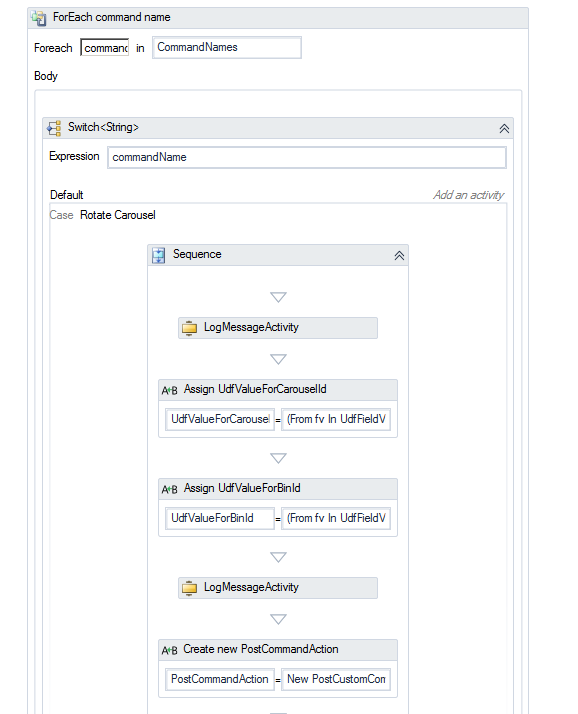

Custom Commands (Execute)

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

EntityType |

In |

EntityTypeEnum |

|

|

EntityId |

In |

String |

|

|

CommandNames |

In |

List<String> |

|

|

PostCustomCommandActions |

Out |

List<PostCustomCommands. |

|

This workflow is used to execute a list of commands for an entity (Type/Id) and return a list of PostCommandActions

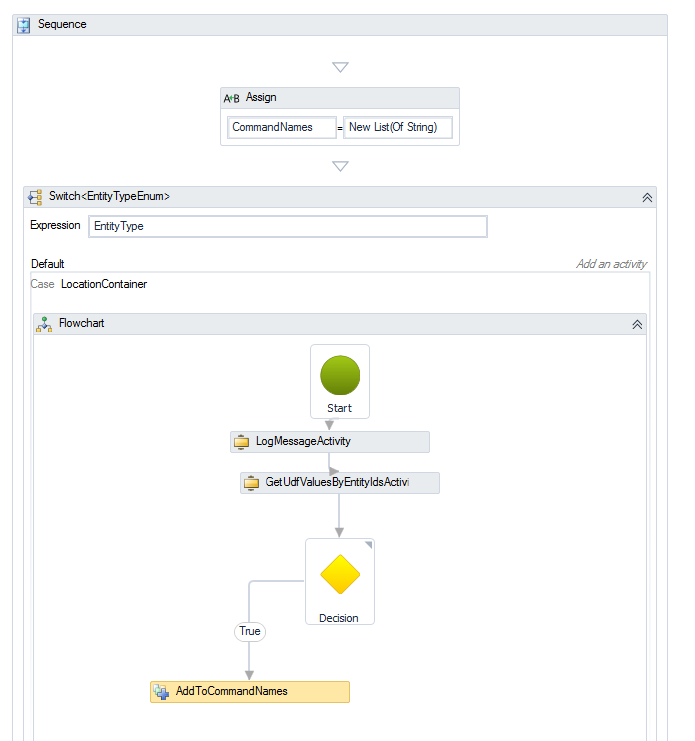

Custom Commands (Get)

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

EntityType |

In |

EntityTypeEnum |

|

|

EntityId |

In |

String |

|

|

CommandNames |

Out |

List<String> |

|

License Plate Not Found

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

LicensePlateNotFoundContext |

|

|

InputLicensePlateLookupCode |

In |

String |

|

|

InputWarehouseId |

In |

Int32 |

|

|

OutputLicensePlateId |

Out |

Nullable<Int32> |

|

Loading Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputLicensePlateId |

In |

Int32 |

|

|

InputLocationId |

In |

Int32 |

|

|

OutputLocationIsFinalLoad |

Out |

Boolean |

|

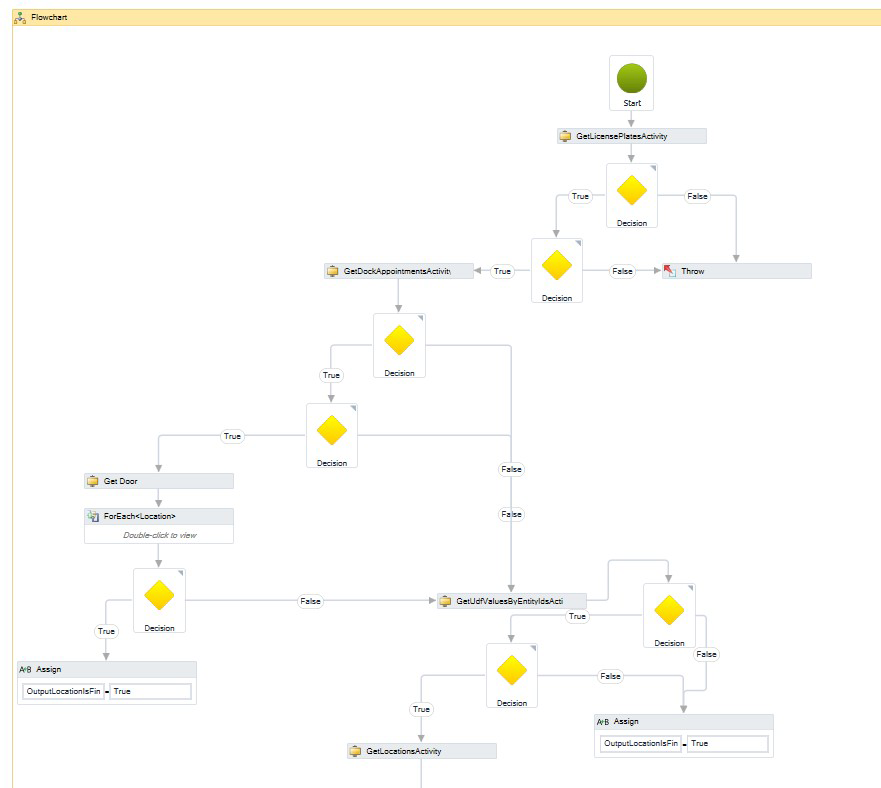

A very specific workflow, Loading Request returns a Boolean value based on licensePlateId and locationId, TRUE indicates it's a final Loading location and FALSE indicates it's a preLoading location.

Manufacturing Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputOutboundOrderId |

In |

Int32 |

|

|

OutputManufacturingRequest |

Out |

ManufacturingRequest |

|

|

InputWarehouseId |

In |

Int32 |

|

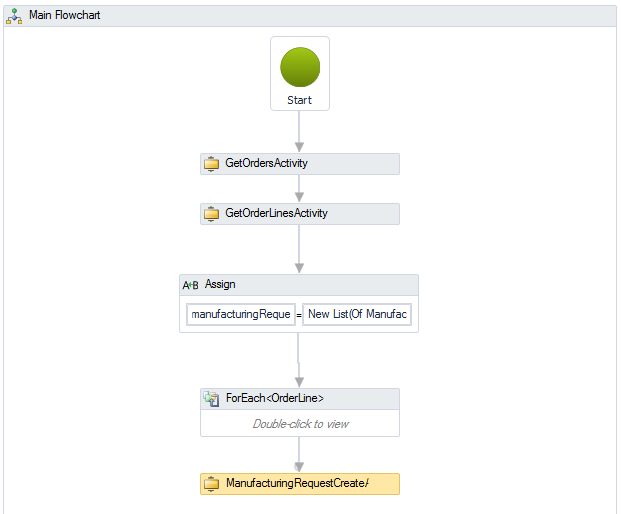

This workflow is triggered whenever a Manufacturing Request needs to be created from Outbound Order.

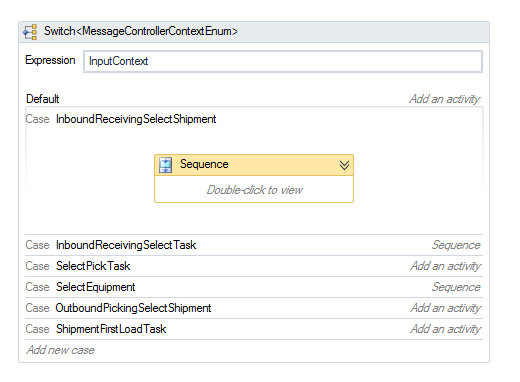

Message Controller

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

MessageControllerContextEnum |

|

|

MessageControllerInput |

In |

MessageControllerInputBase |

|

|

MessageControllerOutput |

Out |

MessageControllerOutputBase |

This workflow is triggered whenever a message needs to be displayed on the mobile device based on a context

Outbound Order Preprocessor

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

Orders MasterOrder |

|

InputMasterOrderId |

In |

?Int32 |

|

|

InputOrderIds |

In |

List<int32> |

|

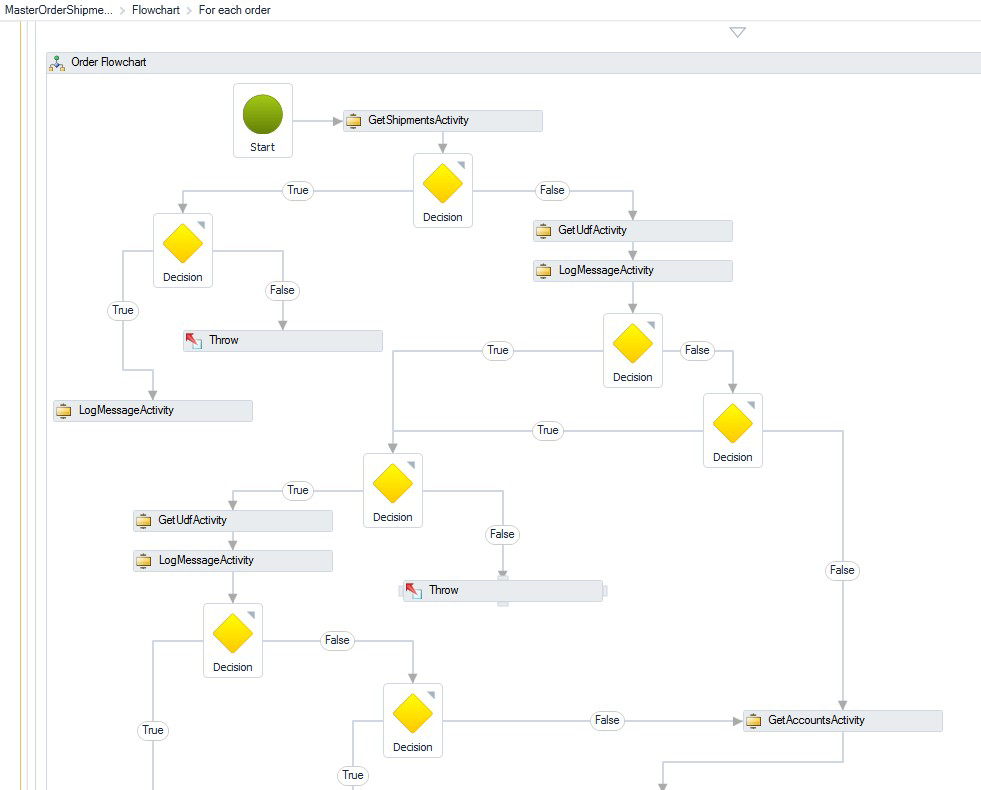

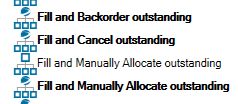

This Workflow will return Shipments for either all the Orders in a Master Order or for a single Order. The workflow is invoked by clicking “Consolidate Shipments” on the master order, or “Auto Assign Shipment” on the Shipment tab of an outbound sales order. From here the workflow can load data about the order and accounts and use this to create new shipments or use it to assign the order lines to an existing shipment.

This Workflow is used to assign shipments to order and/or adjust and create substitute order lines. This workflow in in conflict with Outbound Processing Strategy which does the same job. The invoking of the workflow is the difference. When set active this workflow will always run.

Outbound Packaged Quantities Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

OutboundOrderProcessing OutboundShipmentCartonization |

|

InputOrderId |

In |

Int32 |

|

|

OutputOutboundOrderPackagedQuantities |

Out |

Dicionary<OrderLine, Dictionary<Package,Decimal>> |

|

|

InputShipmentId |

In |

Int32 |

|

|

OutputOutboundShipmentPackagedQuantities |

Out |

Dicionary<ShipmentLine, Dictionary<Package,Decimal>> |

|

This Workflow returns optimized Outbound Package Quantities based on an input order. This workflow will run just prior to processing and cartoization of a outbound order. During the workflow one can alter the order line quantity and package types in the output variable. This could be used to read the material properties first for thing like ready to ship packages, or given each, convert this to case and so on

Outbound Processing Strategy

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputMasterOrderId |

In |

Nullable<Int32> |

|

|

InputOrderIds |

In |

List<Int32> |

|

|

InputShipmentOrderIds |

In |

List<Keyvaluepair<Int32,Int32>> |

|

|

InputOutboundProcessingBehavior |

In |

OutboundProcessingBehavior |

|

|

InputOutboundProcessingFeedback |

In |

OutboundProcessingFeedback |

This workflow is trigger by end users in Footprint when processing outbound order. The use would choose the processing specifically. The intent of this workflow is to handle the processing of order line and possible creation of shipments. When this workflow it is possible to turn order line of kits into kit quantities as sub line. One can use this workflow to find substitute material and add them as order lines under the original parent. In another case this workflow can look at all the inventory and create shipment based on warehouse. There are many possibilities with this workflow

Prepare Shipping Packages for Manifest

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

Context |

In |

String |

|

|

ShippingPackages |

In/Out |

List< ShippingPackage> |

|

This Workflow will prepare shipping packages to be manifested.

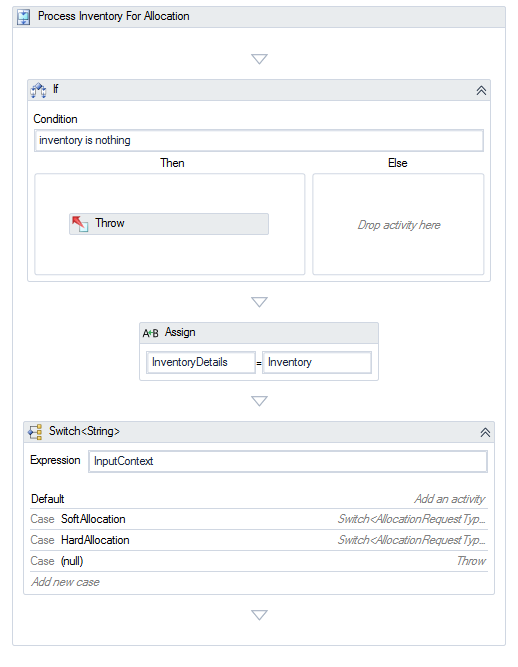

Process Inventory For Allocation

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputRequest |

In |

AllocationRequest |

|

|

Inventory |

In/Out |

List<Inventory> |

|

This Workflow will process the inventory records before the soft allocation check is done or the allocation engine tries to allocate inventory.

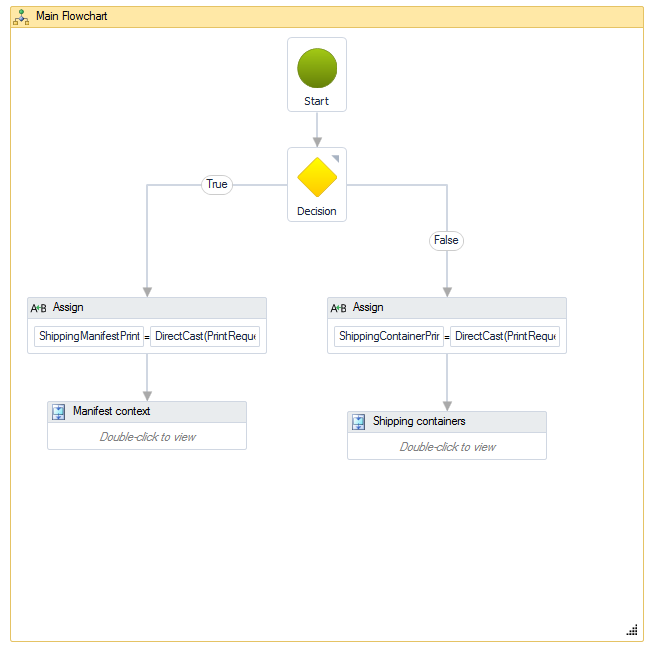

Process Print Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

Context |

In |

String |

ShippingManifest Shippingcontainers |

|

PrintRequest |

In |

PrintRequest |

|

|

PrintItems |

Out |

List< > |

|

This Workflow will process a print request trigger from the Manifest and rate and ship screens. The input in a PrintRequest that contains a list of reports, labels, that Connectship, FootPrint, and other third party printing software FootPrint supports integration with. The workflow can be customized to remove items, automatic select items, set the printers, format, orientation, paper type and copies, based on data in the shipping container or manifest.

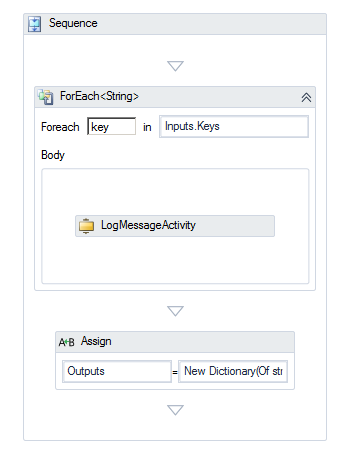

Public

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

Inputs |

In |

Dictionary<String,Object> |

|

|

Outputs |

Out |

Dictionary<String,Object> |

|

This workflow is triggered by the FootPrint Explorer API. It is exposed here to allow users of the API to design and create their own workflows and functions. These are they only public workflow that FootPrint exposes.

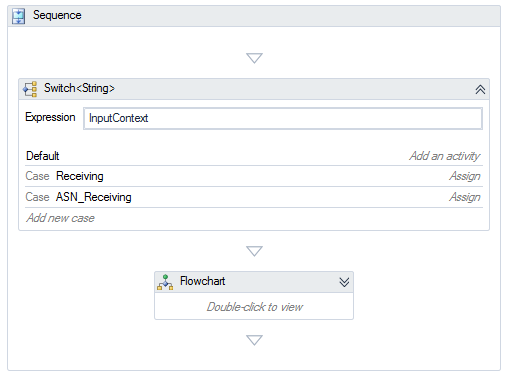

Receiving Request

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputShipmentOrderIds |

In |

List<Keyvaluepair<Int32,Int32>> |

|

|

InputReceivingRequest |

In |

ReceivingRequest |

|

|

OutputReceivingResult |

Out |

ReceivingResult |

|

Recommend Inventory Location

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

This is provided by FootPrInt32 user Int32erface and details the context for either a Inventory Move or a License Plate Move. The value is either{ "InventoryMove", “LicensePlateMove”} |

|

InputLicensePlate |

In |

LicensePlate |

The License Plate details. Applies to both inventory move and license plate moves |

|

OutputLocation |

Out |

Location |

The expected output Location of the workflow |

|

InputLot |

In |

Lot |

If this a Inventory Move, then the select Lot details are provided in this parameter. Otherwise this field is Nothing |

|

InputPackage |

In |

Package |

If this a Inventory Move, then the selected Packaging details are provided in this parameter. Otherwise this field is Nothing |

|

InputPackageAmount |

In |

Decimal |

If this a Inventory Move, then the selected quantity details are provided in this parameter. Otherwise this field is Nothing |

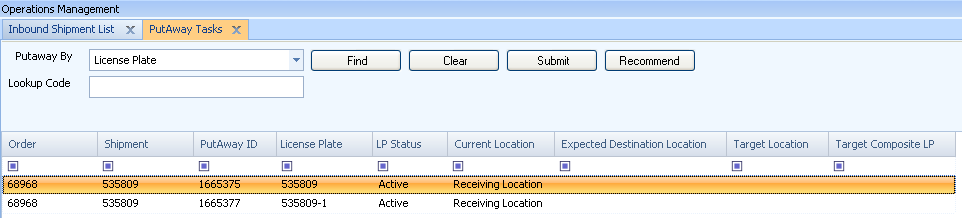

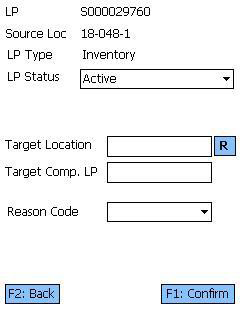

This workflow is called by request of the end user by using the Recommend ([R]) button on the desktop or Mobile from the Putaway screens, or License Plate Move or Directed Move, and Inventory Move or Directed Move. When the button is clicked from the UI it will take the selected record’s values as the input context and data for the workflow. Then execute the workflow that has been designed. The workflow must assign a value to the OutputLocation the output of the workflow function. This Output is what is then displayed in the user interface in the Target Location field.

Recommend License Plate Location

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

This is provided by FootPrInt32 user Int32erface and details the context for either a Inventory Move or a License Plate Move. The value is either{ "InventoryMove", “LicensePlateMove”} |

|

InputLicensePlate |

In |

LicensePlate |

The License Plate details. Applies to both inventory move and license plate moves |

|

OutputLocation |

Out |

Location |

The expected output Location of the workflow |

|

InputLot |

In |

Lot |

If this a Inventory Move, then the select Lot details are provided in this parameter. Otherwise this field is Nothing |

|

InputPackage |

In |

Package |

If this a Inventory Move, then the selected Packaging details are provided in this parameter. Otherwise this field is Nothing |

|

InputPackageAmount |

In |

Decimal |

If this a Inventory Move, then the selected quantity details are provided in this parameter. Otherwise this field is Nothing |

This workflow is called by request of the end user by using the Recommend ([R]) button on the desktop or Mobile from the Putaway screens, or License Plate Move or Directed Move, and Inventory Move or Directed Move. When the button is clicked from the UI it will take the selected record’s values as the input context and data for the workflow. Then execute the workflow that has been designed. The workflow must assign a value to the OutputLocation the output of the workflow function. This Output is what is then displayed in the user interface in the Target Location field.

Recommend Lot/VendorLot

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

RecommendedLotVendorLotContextBase |

|

|

InputRecommendationRequest |

In |

LotVendorLotRecommendedRequestBase |

|

|

OutputRecommendationResponse |

Out |

LotVendorLotRecommendedResponseBase |

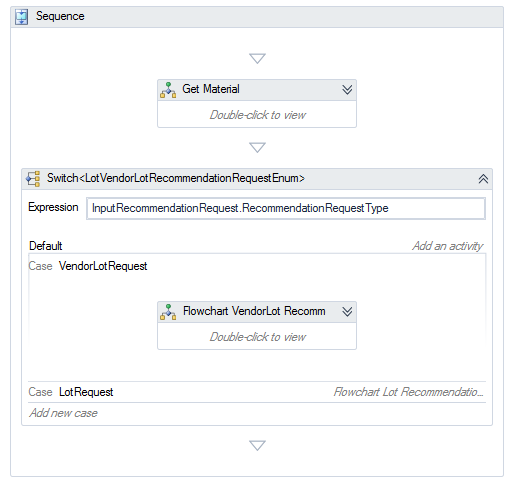

This workflow is used to recommend an existing Lot/VendorLot or creation of a new one. It can be use to create lookupcode that match the input manufacturing date; or create Julian formatted lookup codes; or set the dates for a lot lookup code.

Recommend Receiving Location

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputShipment |

In |

Shipment |

|

|

InputWarehouse |

In |

Warehouse |

|

|

OutputLocation |

Out |

Location |

|

Recurring Storage Custom Billing

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

LicensePlateContents |

In |

List<recurringStorageLicenseplates> |

|

|

BillableValueUom |

In |

MeasementUnitEnum |

|

|

BillableValue |

out |

Decimal |

|

This workflow is given a set of license plates, its goal is to return a billable value

Scale Ticket Receiving

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputRequest |

In |

ScaleTicketReceivingRequest |

|

|

OutputObject |

Out |

ScaleTicketReceivingTasksResult |

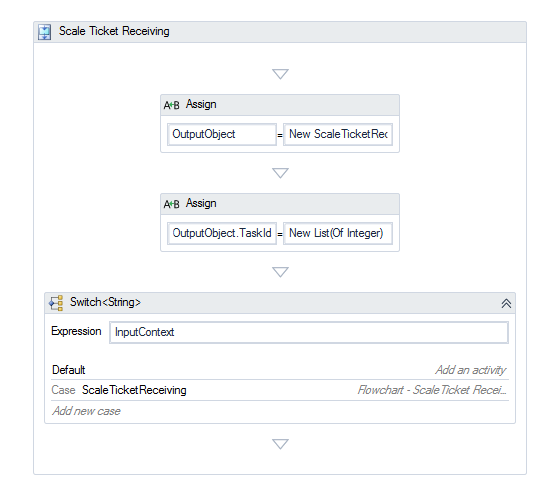

This workflow is called during a receiving by way a scale. Its intent is to create the receiving task based on the inputted request line. It is a way to inject actions during the process.

Scheduled Workflows

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputParameters |

In |

Dictionary<String,String> |

|

|

OutputNotes |

Out |

String |

|

These workflows can be assigned to a scheduled event and thus are call on a routine time. They are useful in they can be designed to synchronize FootPrint data with third party system or can be used to clean up data within the system or trigger alerts based on how data is set.

Shipping Container Weight Verification

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

ShippingContainer |

In |

ShippingContainer |

|

|

MeasuredWeight |

In |

Decimal |

|

|

WeightUom |

In |

String |

|

|

VerificationNotes |

Out |

String |

|

|

VerificationSucceeded |

Out |

Boolean |

|

This workflow determines if the measured weight of a shipping container is acceptable based on tolerances defined inside the workflow.

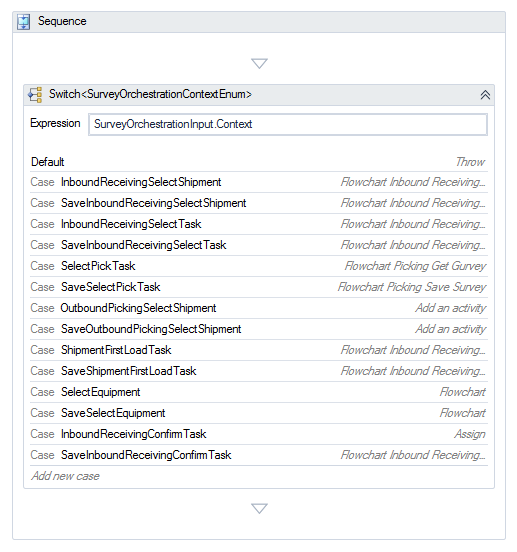

Survey Orchestration

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

SurveyOrchestrationInput |

In |

SurveyOrchestrationInputBase |

|

|

OutputSurveyDefinitionId |

Out |

Nullable Int32 |

|

|

OutputSurveyId |

Out |

Nullable Int32 |

|

This workflow is triggered whenever a survey orchestration is required. Its goal is to get the correct survey (questionnaire) when operations on the mobile are performed. For example after a receiving a pallet the system will ask a series on question about the condition of the pallet.

Wave Release Processing

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputWaveIds |

In |

List of Int32 |

|

|

InputProgressFeedback |

In |

ProgressFeedbackDelegate |

|

This workflow is triggered whenever a wave is released. It allows user to perform operations like printing of packing slips and report on the release

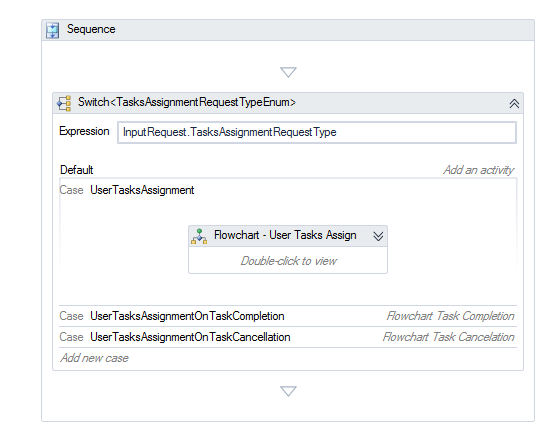

Work Task Assignment

|

Name |

Direction |

Argument Type |

Description |

|---|---|---|---|

|

InputContext |

In |

String |

|

|

InputRequest |

In |

TaskAssignmentRequestBase |

|

| Last Updated: |

| 06/06/2025 |