Create an Inbound Order

Purchase Orders are the beginning of the process to bring inventory into the Warehouse. This Inbound Order specifies what you want, how much of it you want, who you want it from, and how you are going to get it. Once created, the Order can be managed from the Inbound Hub. Inbound Orders can also be imported, copied, or created via configured EDI integrations.

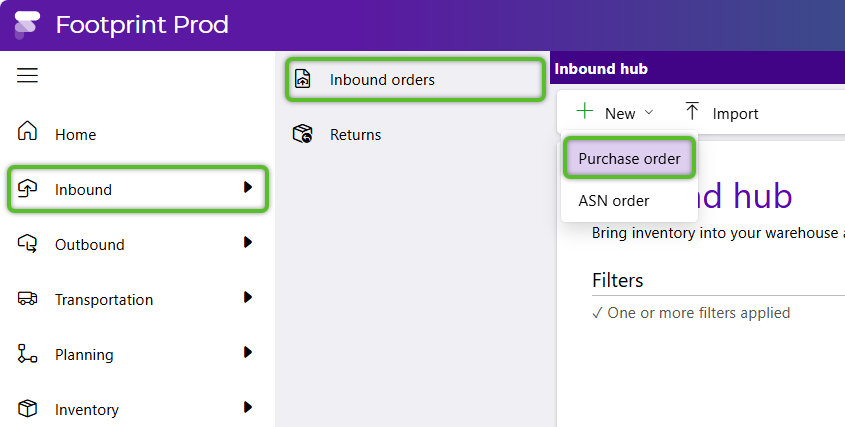

1. From the Inbound Hub, click the option to + Create Purchase Order.

Tip

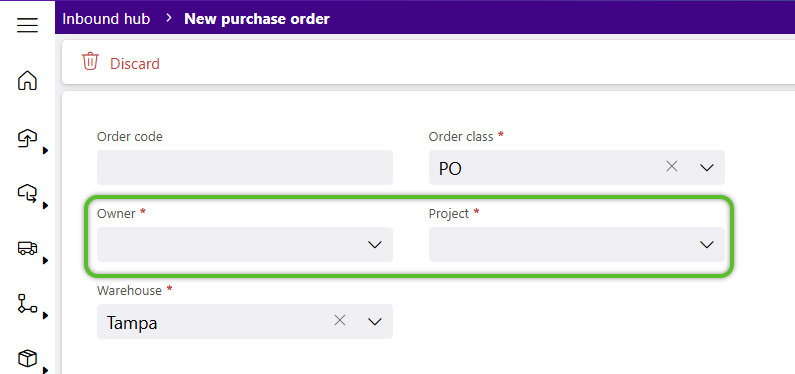

Values already selected in the Inbound Hub Filters, such as Owner, Project, or Warehouse will auto-populate. Otherwise, the Warehouse field populates based on the user's Default Warehouse.

The Lookup will populate an Order number upon creation, unless otherwise specified, and the Order Class defaults to PO.

2. Select the required Owner of the Materials that will be coming.

3. Select the required Project for the Materials and tab out of the field to create the new Inbound Order.

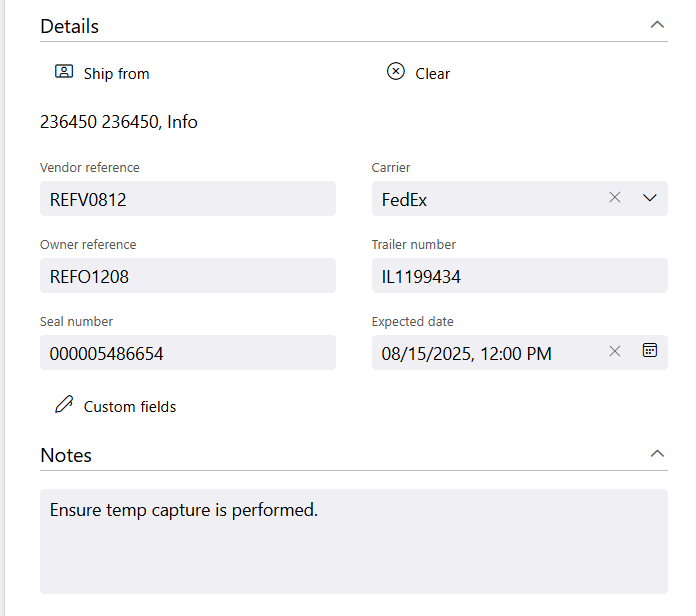

4. To enter optional information about the vendor from whom you are ordering, click to open the Details dropdown.

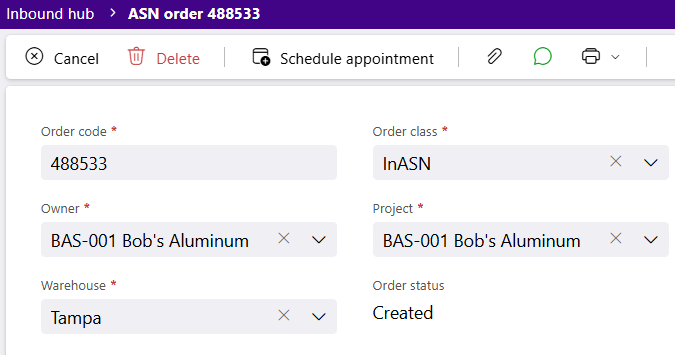

| Lookup: | The Lookup Number for the Order. |

| Order Class: | The Order Class the Order has been assigned to. |

| Owner: | The Name of the Owner for whom the Order was created. |

| Project: | The Name of the Project associated with the Order. |

| Warehouse: | The Warehouse where the Order was Created. |

| Order Status: | The current Status of the Order. |

| Ship From: | The Ship From Address for the Order. |

| Vendor Reference: | The Reference Number given to the Vendor for the Vendor's Reference. |

| Expected Date: | The Date the Delivery is Expected by, if specified in the Order's creation. |

| Carrier: | The Carrier specified for the Order. |

| Owner Reference: | The Reference Number given to the Order for the Owner's Reference. |

| Trailer Number: | The Trailer Number for the Order. |

| Seal Number: | The Seal Number for the Order. |

| Notes: | Any Notes for the Order. |

| Custom Fields: | Specific to your organization. |

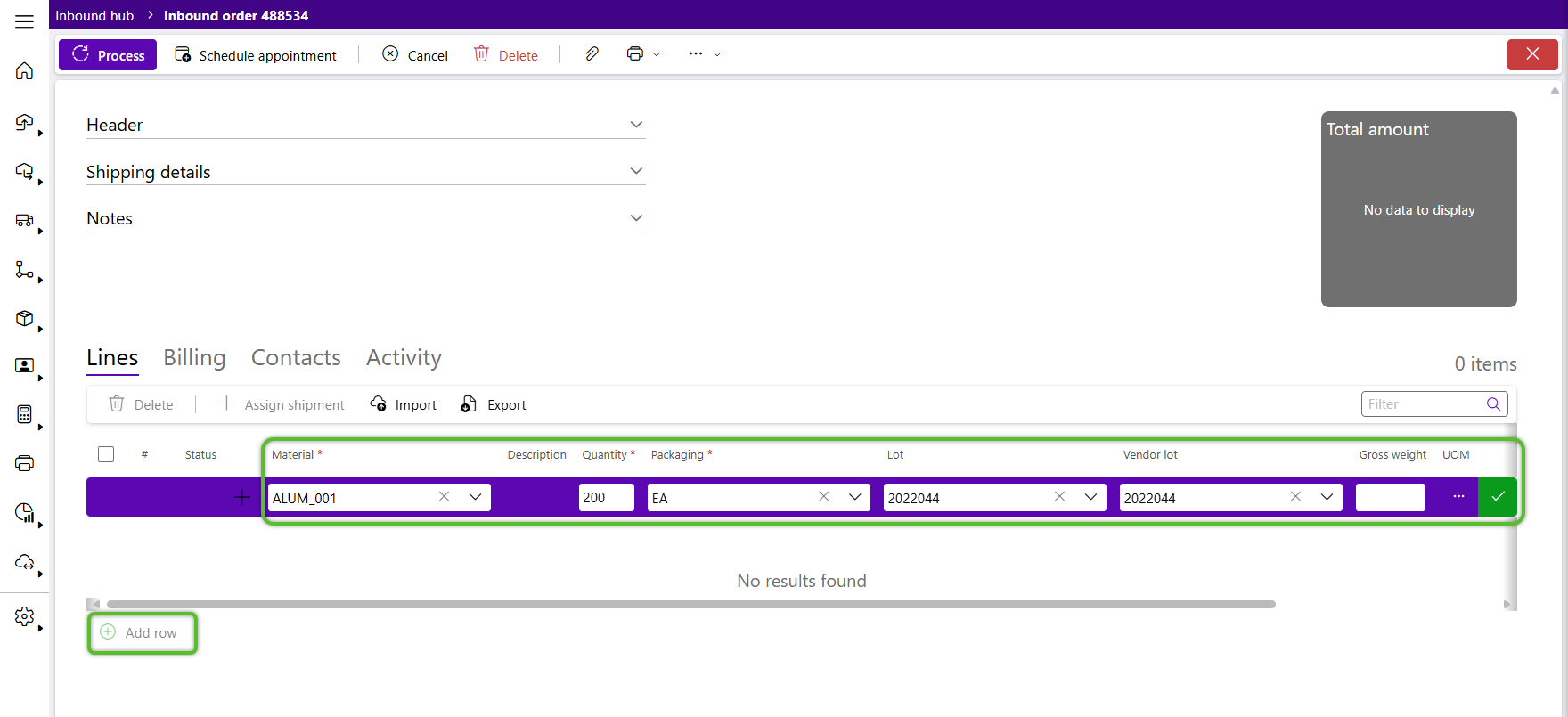

5. Click the green + Add Row option at the bottom of the Lines tab to begin specifying the inventory to Receive.

6. Select a Material from the list available to the Project.

7. Select the correct Packaging and enter the required Quantity.

8. Click the green checkmark at the end of the row.

Repeat steps 5-8 to add more order Lines.

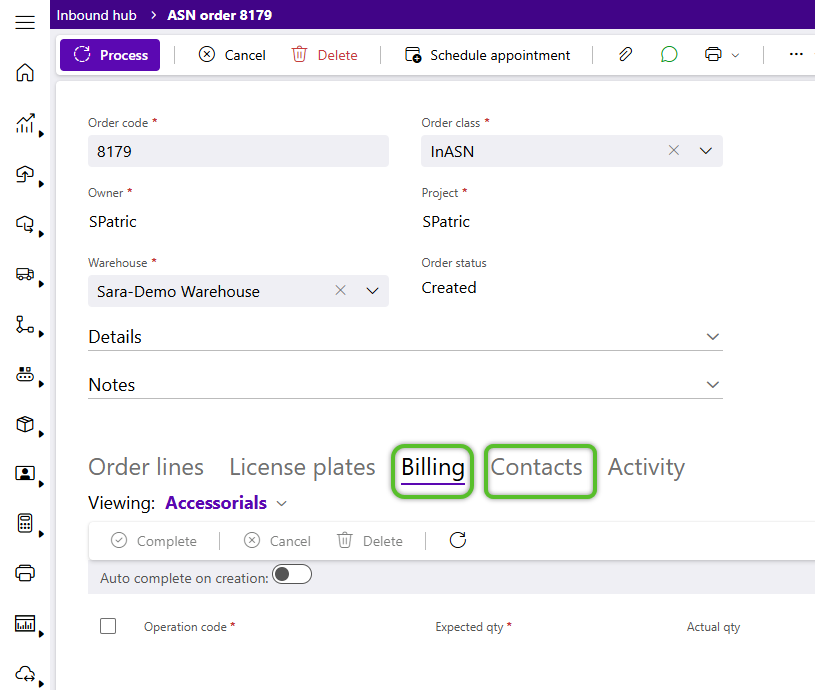

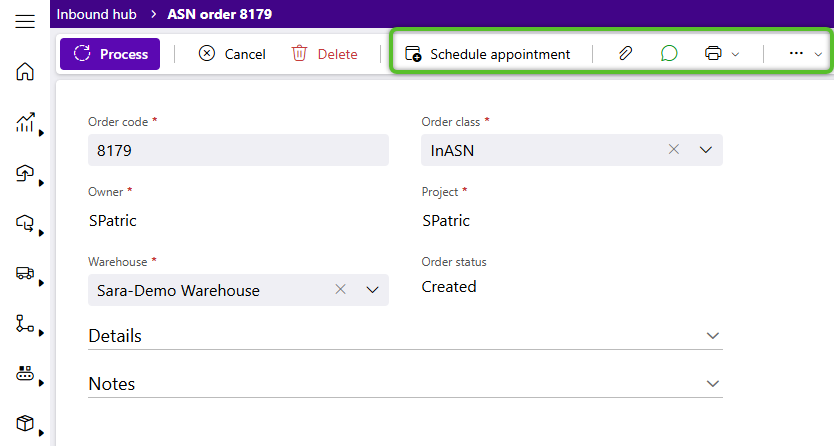

10. Use the Order Toolbar options to Add a Dock Appointment, Add Attachments, Add Comments, Copy the Order, and so on.

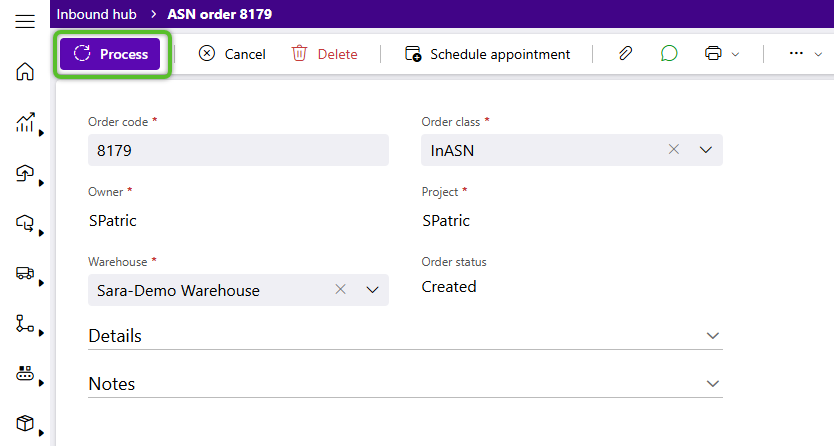

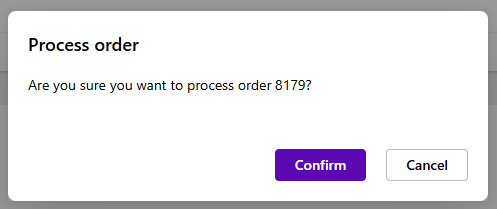

11. Finally, when Receiving for the order may begin, click the Process option in the Order Toolbar.

Note

To Process and Inbound Order, a Default Receiving Location must be set.

Now that you've created and processed the new Inbound Order, Receiving can begin and the order can be managed as needed from the Inbound Hub.

| Last Updated: |

| 08/12/2025 |