Create a Material

Materials are created at the Owner and Project level and describe the specific details of your inventory or product.

Create a new material

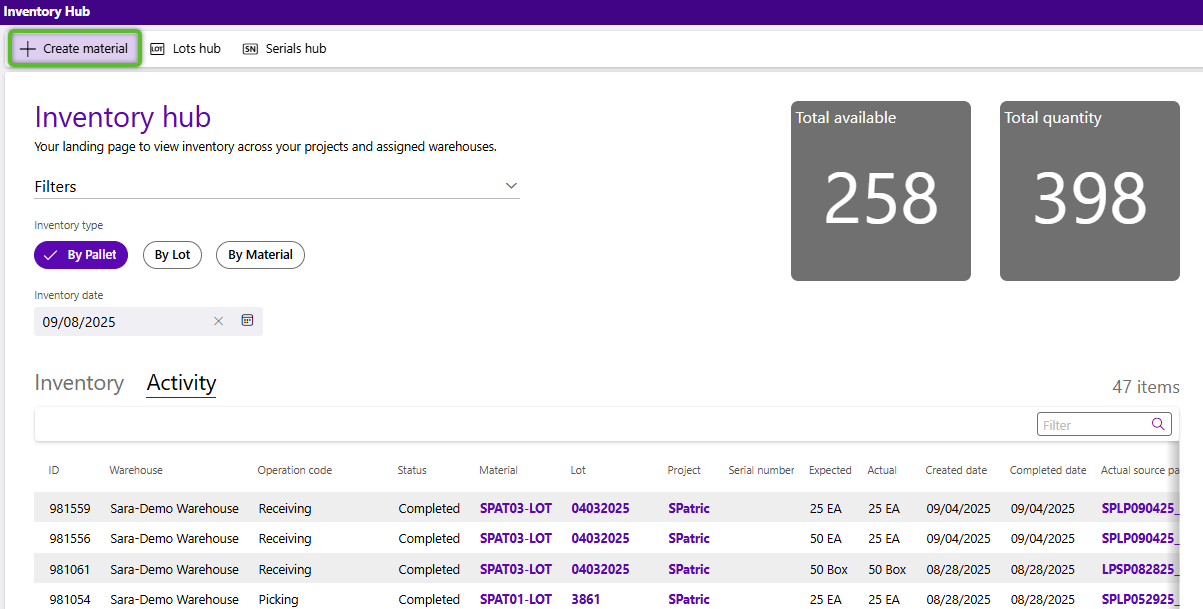

1. Click the + Create material button. Please note you must have an Owner and Project selected under the Filters section (this should happen by default when you open the page).

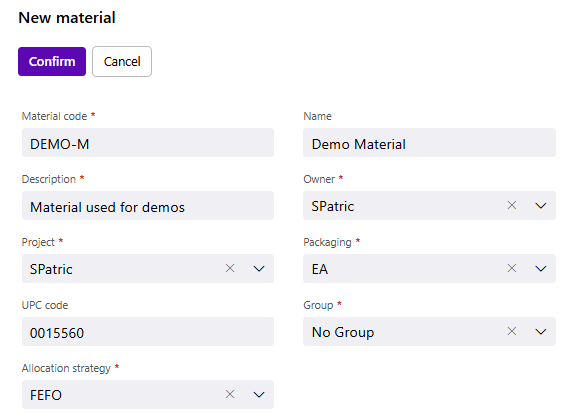

The New material window will open with a form to create a new material. The selected Owner and Project will auto-populate with the values from the Filters section.

2. In the first section of the form, enter a required short Material code that will be used to reference the material, along with a Description of the material. You may add an optional Name that could also be used as an additional identifier.

Note

The required details are indicated with a red asterisk - all other details are optional and can be filled out, but are not necessary. See the Materials Guide for more information.

3. Select the Packaging the material will be in from the drop down. Please note if you have multiple types of packaging - for example, eaches and cases - you should select the lowest packaging level. You will be able to add additional packaging levels after creating the material. Additionally, you also have the option to add a UPC code that will be specific to the selected packaging level.

4. Select a Group used to identify groupings of similar materials. "No group" is an out-of-the-box option if you don't plan to utilize the feature.

5. Select an Allocation Strategy. The Allocation Strategy takes into account related material information when determining what inventory to select for a shipping order. This allows Inventory to be selected to Ship based on set preferences. For example, First Expired, First Out (FEFO) and First In, First Out (FIFO).

- FEFO - First Expired, First Out. Lot controlled inventory whose expiration dates are nearest are assigned to orders.

- FIFO - First In, First Out. The inventory that was received to the warehouse first is selected for orders before newer inventory.

- FMFO - First Manufactured, First Out. The Inventory that were originally manufactured first is assigned to orders before newer materials.

- LEFO - Last Expired, First Out. The inventory whose expiration dates are furthest away are assigned to orders.

By selecting which option you would prefer here, the system automatically utilizes the information selected here when determining inventory to pick and ship for orders.

Tip

Expiration driven strategies will only work when the inventory is lot controlled.

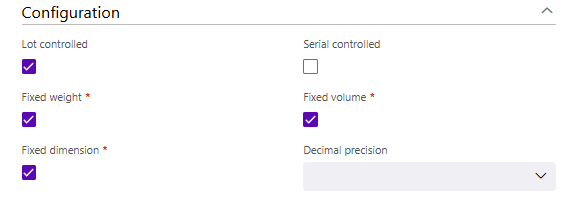

6. To track inventory for this material by individual lots, check the Lot controlled option.

7. If the inventory for the material is to be serial controlled or utilize serial numbers for tracking check the Serial controlled option.

If tracking of lots/serial numbers is not required, leave both toggles off. In such cases inventory for the lot will be assigned a Generic Lot, or GLot and not utilize serial numbers.

If tracking both lots and serial numbers/custom fields, toggle on both options.

8. Select the appropriate "Fixed" box if the product weight, volume, and/or dimension will remain the same. Optionally, set the Decimal precision of these measurements.

Warning

Once you have inventory for this material in the system you will not be able to change these values, so be certain of the whether or not the material will be lot and/or serial controlled and will have a fixed weight or volume.

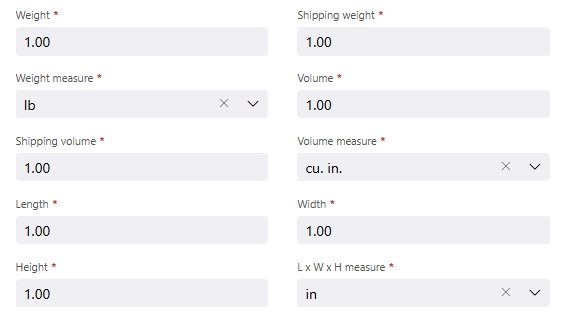

9. If the material has a Fixed weight, specify the Weight (weight before additional shipping packaging) and Shipping weight (total weight), then select the Weight measure.

10. If the material has a Fixed volume, specify the Volume (weight before additional shipping packaging) and Shipping volume (total volume), then select the Volume measure.

11. If the material has a Fixed dimensions, specify the material's Length, Width, and Height, then select the L x W x H Measure.

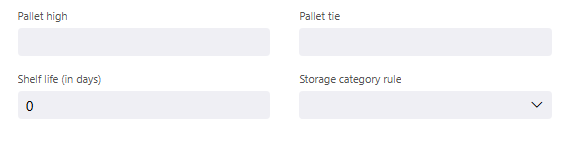

12. (Optional)Enter the Pallet High and Pallet Tie.

Pallet High is how many units high the package can be stacked atop itself, while the Pallet Tie is how many units to set down per level before stacking.

13. (Optional) If the material is lot controlled, you may set the material's Shelf Life (how many days before the lot controlled material expires).

14. (Optional) Select a Storage Category Rule which can be used to determine where in a warehouse inventory for this material can and cannot be stored.

15. Once all fields are set, return to the top of the window and click the Confirm button.

Once a Material has been created edits can still be made, however once inventory has been added for the material, Lot controlled, Serial controlled, Fixed weight, Fixed volume, and Fixed dimensions cannot be changed.

| Last Updated: |

| 09/12/2025 |