Sections

Related Tutorials

Overview

Locations can be manually Replenished, and Released Replenishment Tasks can be completed in the Replenishment section. Before Replenishment can occur, Replenishment Rules must be set up in a Location (see the Warehouse Explorer guide). Replenishment Tasks must be scheduled for creation in the Event Scheduler.

From here you can...

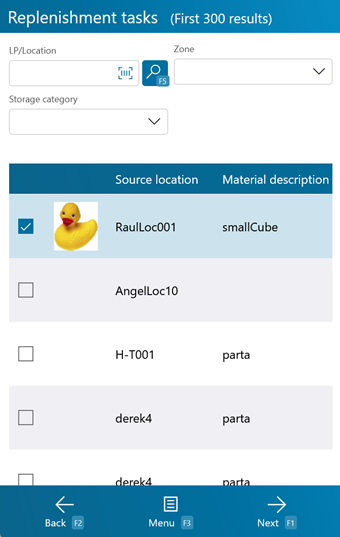

Replenishment Tasks

This screen allows you to search the system for Released Replenishment Tasks.

Before loading Tasks, you can enter information in the LP/Location, Zone, or Storage Location fields to refine the Replenishment Tasks displayed.

Tapping Next: F1 or pressing the F1 key takes you to the Replenishment screen where you can complete the selected Replenishment Task.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Refresh: F5 populates all Released Replenishment Tasks into the list.

- Replenishments: F8 takes you to the On Demand Replenishments screen.

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key takes you back to the main menu.

| [Image]: | The system will display an image of the Materials, when available. |

| Source Location: | The system determined Source Location from which the Materials will be Moved. |

| Material Description: | A description of the Material to be Replenished. |

| Quantity: | The number of Packages of the Material to be Moved to the Target Location. |

| Material: | The Material that is to be Replenished. |

| Source LP: | The recommended Source License Plate from which the Materials can be Moved. |

| Target Location: | The Location to which the Materials are being Moved. |

| Target LP:: | The recommended License Plate onto which the Materials can be Moved. |

| Lot: | The Lot for the Materials to be Replenished. |

| Vendor Lot: | The Vendor Lot for the Materials to be Replenished. |

| Packaging: | The Packaging Type for the Materials to be Moved. |

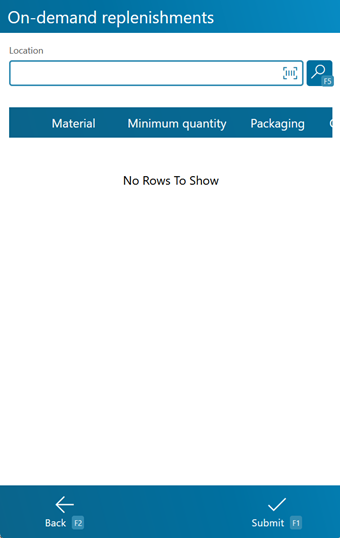

On Demand Replenishments

Pressing the F8 key takes you to the On Demand Replenishments screen, where you can perform Replenishments for Locations that have On Demand enabled in their Replenishment Rules. These Replenishments are performed as needed.

When the Footprint System Setting MobileOnDemandReplenishmentShowAll is set to True, all Replenishments set up for the Location will be displayed here, even when the current Quantity in the Location is greater than the Minimum threshold set to allow for Replenishment. When that system setting is set the False, only Replenishments that are below the Minimum will be shown here.

By scanning or entering a Location (and pressing the Tab key), all On Demand Replenishment requirements for the Location will be populated.

Tapping Submit: F1 or pressing the F1 key completes the Replenishment, Moving the Materials to their new Location in the system.

Tapping Back: F2 or pressing the F2 key takes you back to the Replenishment Tasks screen.

| [Box]: | Place a check mark in this box by tapping it to perform a Replenishment of the specified Materials. |

| Material: | The Material that is to be Replenished. |

| Minimum Quantity: | The lowest number of Packages of the Material that can be in the Location without requiring Replenishment. |

| Packaging: | The Packaging Type for the Minimum Packaged Amount rule. |

| Quantity to Replenish: | The number of Packages of the Material to be moved to this Location when the Available Packaged Amount is lower than the Minimum Packaged Amount. |

| Packaging to Replenish: | The Packaging Type to be Replenished to the Location. |

| Available Base Quantity: | The number of Packages of the Material currently in the Location. |

| Incoming Base Quantity: | The number of Packages of the Material coming into the Location. |

| Base Package: | The name of the Package. |

| Maximum Quantity: | The maximum number of Packages of Material that can be held in the Location. |

| Packaging: | The Packaging Type for the Materials in the Location. |

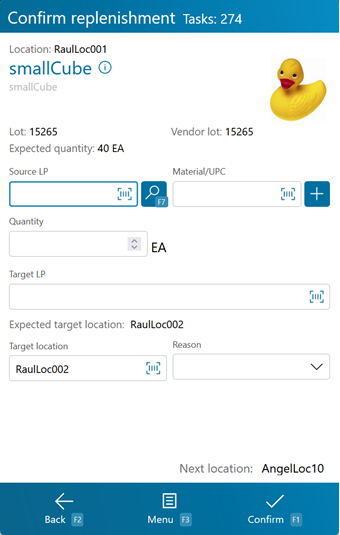

Replenishment

This is where you actually complete the Replenishment.

Tapping Confirm: F1 or pressing the F1 key completes the Replenishment, Moving the Materials to their new Location in the system.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Select Source LP: F7 bring up the LP Inquiry to select the Source LP.

- Reallocate: F8 takes you to the Reallocation screen.

- Inquiry: F11 opens the Inquiry Menu.

- Create a Task Notification opens the Notification screen to create an alert.

- Increase Qty on Material Scan toggles the device to increase quantity for each barcode scanned.

- Decrease Qty on Material Scan toggles the device to decrease quantity for each barcode scanned.

- Next Task moves to the next available Replenishment Task.

- Previous Task moves to the previous available Replenishment Task.

Tapping Back: F2 or pressing the F2 key takes you back to the Replenishment Tasks screen.

*Those in red are required fields.

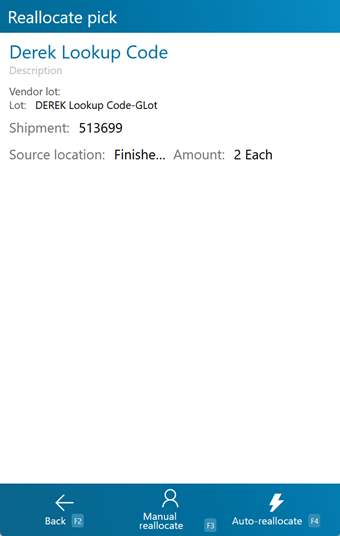

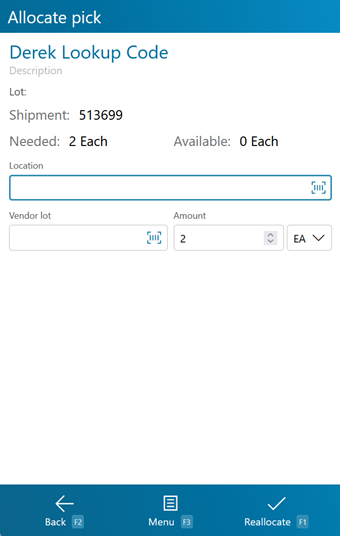

Pressing the F8 key allows you to Reallocate the Materials, using a different Source Location for the Materials.

Tapping Manual Reallocate: F3 or pressing the F3 key allows you to choose the Source Location for the Materials.

Tapping Auto-Reallocate: F4 or pressing the F4 key has the system choose a new Source Location for the Materials.

Tapping Back: F2 or pressing the F2 key takes you back to the previous screen.

| Material: | The Material to be Reallocated. |

| Vendor Lot: | The Vendor Lot for the Materials to be Reallocated. |

| Lot: | The Lot for the Materials to be Reallocated. |

| Shipment: | The Shipment for the Materials to be Reallocated, if applicable. |

| Source Location: | The current Source Location from which the Materials have been Allocated. |

| Amount: | The number of Packages of the Material to be Reallocated. |

Tapping Next: F1or pressing the F1 key completes the Reallocation, changing the Source Location.

Tapping Menu: F3 or pressing the F3 key displays a menu with these additional options:

- Inquiry: F11 opens the Inquiry Menu.

Tapping Back: F2 or pressing the F2 key takes you back to the previous screen.

| Material: | The Material to be Reallocated. |

| Lot: | The Lot for the Materials to be Reallocated. |

| Shipment | The Shipment for which you are Allocating. |

| Needed: | The expected number of Materials for the Shipment. |

| Available: | The number of Materials in the Location available to be Allocated. |

| Location: | Enter the new Source Location from which the Materials will be Allocated. |

| Vendor Lot: | The Vendor Lot for the Materials to be Reallocated. |

| Amount: | The number of Packages of the Material to Reallocate. The Packaging Type is displayed next to the field. |

| UOM: | The Material's Unit of Measure. |

*Those in red are required fields.

| Last Updated: |

| 06/06/2025 |