Inventory

Sections

Overview

Because it is the reason for your Warehouse in the first place, Footprint handles Inventory in an exhaustive fashion. As such, there is quite a bit of information associated with each piece of Inventory in the system, which can become complex and at times confusing. Here we take a look at exactly how Inventory is defined in Footprint.

For information on the physical storage of Inventory, see the Physical Hierarchy Concept page.

Materials

Inventory is referred to as Materials in Footprint. A Material is a good, product, or whatever else you'd like to call your Inventory; we call it a Material.

Inventory is grouped together by Materials, which are associated with Material Groups and Global Materials. Materials are divided into Lots and Vendor Lots, and individual Materials can be tracked by an associated Serial Number.

Materials

A Material explains what a type of inventory is - every item in your Warehouse belongs to a Material. Individual items are described as a Quantity of a particular Material, and can be identified by unique Serial Numbers when necessary.

For example, Swiss Cheese may be used as a Material. Every piece of Swiss cheese that enters the Warehouse will be entered in Footprint as the Swiss Cheese Material.

Materials define a great deal of information about inventory, most importantly the Owner and Project the Material belongs to, and what details about the Material are tracked.

Ownership - All Materials belong to both an Owner and a Project. This information is determined at the Material level, and thus any and all Materials of the same type belong to the same Owner, and are classified under the same Project.

Control Type - The Control Type for inventory is set at the Material level, specifying whether each Material of this type needs to be tracked by Lot, Serial Number, neither, or both.

Lifetime Properties - A Material's Lifetime Properties set the shelf life of all inventory of this type.

Allocation - a Material's Allocation influences which individual Materials are used for Shipments or Manufacturing, which can be set in a number of ways based on the individual Material's expiration dates, the date they entered the Warehouse, their Packaging, and so on.

Packaging - A Material can have multiple levels of Packaging set up, not only describing the physical dimensions of the Material itself, but also allowing multiple boxes to be stored in a container, for example. These settings are completely customizable, and determine what Packaging options are available to the Material when setting up Orders.

Materials must be tied to a Global Material and be classified under a Material Group.

Global Materials

Material Groups are a way of grouping the same Materials across different Owners, as Materials are tied to one Owner and Project each. For example, the Swiss Cheese Material might be connected to the Swiss Cheese Global Material - same name, but grouping Swiss Cheese from all Projects.

Global Material are typically used for Reporting and Billing purposes, as Reports and Contract Lines can be filtered by Material Group.

Each Material must be tied to one Global Material, and Global Materials can be tied to as many different Materials as desired.

Material Groups

Material Groups are a high-level classification of Materials. For example, the Swiss Cheese Material might be under the Cheese Material Group, along with Cheddar Cheese and Pepper Jack Cheese.

Material Groups are typically used for Reporting and Billing purposes, as Reports and Contract Lines can be filtered by Material Group. Material Groups can also have a Temperature Category Rule defined for them, which new Materials under the Group will default to.

Each Material must be grouped under a Material Group, and Material Groups can be group together as many different Materials as desired.

Lots and Vendor Lots

When a Material is Lot Controlled (its Control Type is either Lots or LotsSerial), Footprint will track unique Lots and Vendor Lots for each Material of that type. This means creating Lot and Vendor Lot Entities that are directly tied to the Material for which they are created.

Vendor Lots represent the vendor-assigned identification of a particular group of Materials, all sharing the same Manufacturing and Expiration Dates.

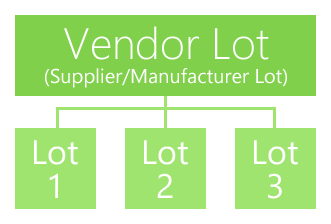

Lots are sub-divisions of Vendor Lots, which share the same information as provided by their parent Vendor Lot, but have an additional Description and Notes. Each Vendor Lot must have at least one Lot.

Lot Controlled Materials are grouped together under Vendor Lots and Lots. For example, the Swiss Cheese Material could be under the 03-15 Vendor Lot, and further under the 03-21 Lot. This allows you to tell apart the batch of Swiss cheese manufactured on 03/15 from the rest of the Swiss cheese in the Warehouse, as well as the specific portion of that batch that was received on 03/21.

Tip

Lots and Vendor Lots can be used however best fits a Warehouse's needs.

GLot

Materials that are not Lot Controlled (with a Control Type of either MaterialLot or MaterialLotSerial) are assigned a Generic Lot, or GLot. Each unit of the Material will automatically be assigned this as their Lot and Vendor Lot, eliminating the need to enter any information in these fields. The name of a Material's GLot includes the Material's name - for example, a Material CheeseKnife-01 would have the G-Lot CheeseKnife-01-GLot.

Serial Numbers

For more information, see the Serial Numbers Concept page.

When a Material is Serial Controlled (its Control Type is either LotsSerial or MaterialLotSerial), Footprint will track unique Serial Numbers for each Material of that type.

Serial Numbers are a way of identifying each individual item under that Material, rather than remaining anonymous within the Quantity of that type. Additional information about individual Materials can be tied to Serial Numbers in the form of User Defined Fields, and this information, along with a unique Task History (detailing where the Material has been at what time, its past Statuses, and so on) is kept with the Serial Number as well.

Serial Numbers are also used to track Variable Weights and Variable Lengths for Materials, so that the precise measurement for each Material is recorded in Footprint. For any item that is not Serial Controlled but uses Variable Weights or Variable Dimensions, the system will automatically create and assign the item a Serial Number to track it by.

For example, the Swiss Cheese Material could have MC-001 as its Serial Number. The information tied to that Serial Number is how you know that particular chunk of cheese weighs 2000 pounds.

| Last Updated: |

| 06/06/2025 |